We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

It’s hard to say that a workshop is actually a workshop if there isn’t at least a small workbench somewhere within the space. While premade workbenches can be costly and you may not even be able to find a workshop table that appeals to you, there is an alternative: You can make your own! Learning how to build a workbench doesn’t have to be hard. If you follow any of these 16 DIY workbench plans, you can create a homemade workbench that will increase your productivity and pleasure in the workshop.

1. Bob Vila’s Downloadable Workbench Plans

This shapeshifting workbench is easier to build than you might think—especially with the detailed cut list, step-by-step photos, and clear illustrations included with the downloadable plans. The finished project is mobile and can collapse down to fit within just 2 feet by 4 feet of floor space, all while keeping the integrated storage cabinet easily accessible. When unfolded, Bob Vila’s sturdy workbench doubles in size and can lend a helping hand with countless DIY jobs around the house. You can lock down the casters and moveable parts for stability, and it’s easy to incorporate more customizations to suit your needs and space.

Get Bob Vila’s Downloadable Workbench Plans Now for $4.99

2. The Ultimate Workbench

If you’ve been searching for advanced worktable plans then downloading these plans for the ultimate workbench may satisfy your need for a challenging DIY project. These plans include detailed instructions for creating a huge 4-foot by 8-foot workbench that’s equipped with an integrated dust collection system and power outlets, making it easy to operate a range of power tools without needing to run an extension cord across the workshop.

Get the Ultimate Workbench Woodworking Plans at Etsy for $20

3. Wall-Mounted Worktable

Create a simple space-saving workbench by following these detailed plans for a small, wall-mounted worktable. The unique workbench design takes advantage of available wall space to save a significant amount of floor space. It has a folding mechanism on the tabletop of the workbench and also on the three workbench supports, allowing the entire workbench to fold back against the wall. When folded, it takes up no more than 6 inches of space.

Get the Wall-Mounted Worktable Plans at Etsy for $9.99

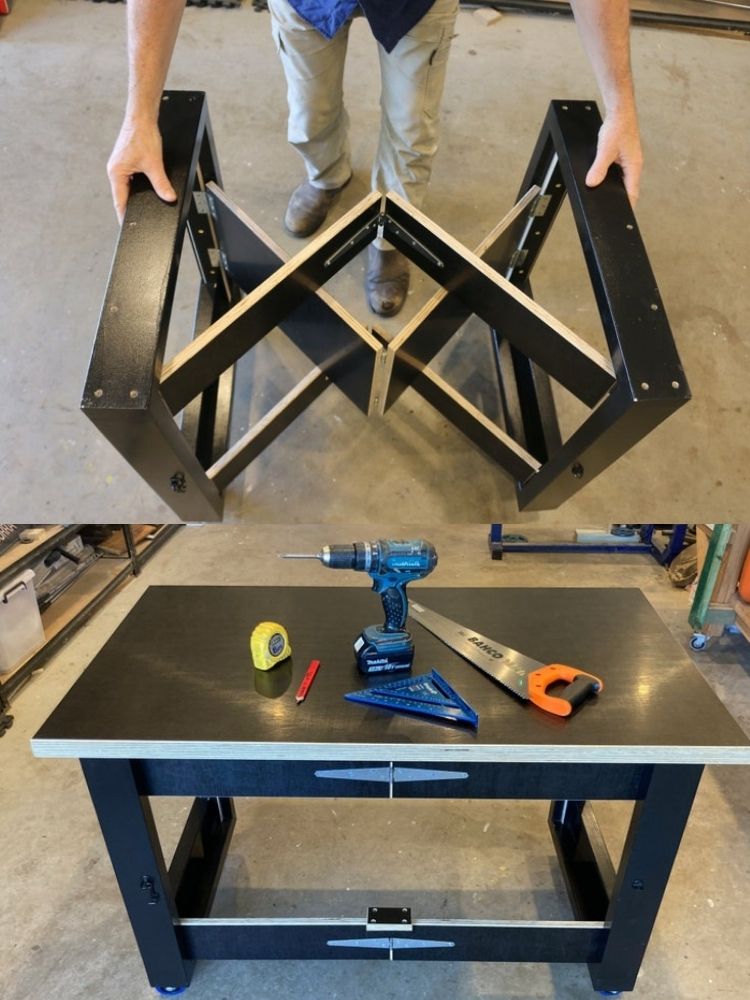

4. Small Folding Workbench

Tackle home DIY projects with this solid structural plywood workbench that can be folded up and slid aside when it’s no longer needed, saving space in a small workshop. The entire workbench sits on four wheels. When it’s folded up, the workbench can be rolled around on flat surfaces without an issue.

Get the DIY Folding Workbench Plans at Etsy for $5.85

5. 2×4 Workbench Plans

Use these plans, available for instant download, to fashion your own 2×4 workbench for a garage, shed, or workshop. The workbench features four locking wheels and it’s designed with two large storage shelves on either side of the workbench. It also has a single storage space in the center where hardware organizers can be kept neatly on the evenly spaced slats. The workbench is 6.25 feet wide, 1.83 feet deep, and 2.96 feet tall.

Get the 2×4 Workbench Woodworking Plans at Etsy for $8

6. Workbench With Vertical Storage

Many DIYers enjoy extra storage in the shed, garage, or workshop for tools, supplies, and projects. These homemade workbench plans include a pegboard tool organizer, and are a great choice for those DIYers who enjoy maxing out storage and shop furniture that offers multifunctions. The heavy-duty workbench features a broad worktable that stretches 2.25 feet in depth and 5.7 feet in length. Its 5.8-foot height includes a large storage shelf that can hold multiple power tools and an entire toolbox.

Get the Heavy Duty Workbench Plans at Etsy for $8.95

7. Flip-Top Workbench

Craft this impressive double flip-top workbench to help improve efficiency in the workshop. The workbench plans provide clear instructions for creating two flipping stations that allow you to fasten a power tool to the workbench like a planer or miter saw. Once in place, the tool can be used as normal. When you are done with the tool, just flip the flipping station to store the power tool underneath the worktable. The flat side of the flipping station is then free to use as a tabletop surface.

Get the Double Flip-Flop Workbench Plans at Etsy for $8.75

8.Hidden-Storage Rolling Worktable

This simple homemade workbench measures 2 feet in depth by 4 feet in length. These workbench plans are designed so the entire workbench sits on four caster wheels, making it easy to move the workbench around on any hard, flat surface. The top of the workbench is attached with a pair of hinges and opens to reveal a 4-inch deep by 8-square-foot compartment for storing supplies and tools.

Get the Modular Worktables Plans at Etsy for $7

9. Worktable for Benchtop Tools

For the experienced woodworkers who want to challenge themselves, these comprehensive workbench plans are an appealing option that can guide woodworkers to building a worktable with multiple stations for benchtop tools like a table saw or miter saw. The workbench also has a ton of storage space, and even includes instructions for building a rotary tray for the saw.

Get the Miter Saw/Table Saw Workbench Plans at Etsy for $15

10. Shop Cart Plans

Homemade workbenches don’t need to be huge because sometimes all that’s necessary is a small shop cart like the one featured in these creative workbench plans. The cart is supported by four lockable caster wheels that make it easy to move around on flat hard surfaces. It has a shallow drawer for miscellaneous items, a large cupboard for storing power tools, and two open shelves for quick access to frequently used tools and accessories.

Get the Shop Cart Plans at Etsy for $9.99

11. Fold-Down Mobile Workbench

If you have a smaller workshop or just enjoy the benefits of space-saving products, then these innovative workbench plans are a great choice. The constructed workbench provides 18 square feet of tabletop space and it sits on four lockable caster wheels. When the work is done, you can fold the legs and even hang the entire workbench on the custom wall-mount for simple, space-saving storage.

Get the Foldable Workshop Table Plans at Etsy for $12

12. Table Saw Workbench

As the name implies, these workbench plans give detailed instructions for building a workbench that can integrate with a table saw. The entire workbench remains mobile on larger caster wheels, but a third of the workbench tabletop is cut out to make room for a built-in table saw, complete with a drawer below the table saw station for extra blades, push blocks, or other tools.

Get the Table Saw Workbench Plans at Etsy for $12.99

13. Double-Cabinet Workbench

Get a ton of storage space by following these straightforward directions for building a double cabinet workbench. The workbench is 6.125 feet in width and 2.1 feet in depth with a height of about 3 feet. It’s topped with a sturdy tabletop and features two drawers and two storage cabinets with adjustable shelves that make it easy to organize tools.

Get the Double-Cabinet Workbench Plans at Etsy for $10.99

14. Sturdy, Standard Bench

Not every workbench needs to have a unique design and innovative new features, especially when a sturdy, standard workbench is ideal for most DIY projects. These workbench plans are easy to follow and the result is a 6-foot wide, 3-foot deep solid wood workbench that can handle the everyday wear-and-tear of a busy workshop. The simplicity of the design also makes it an excellent option for new DIYers or experienced DIYers who are looking to build something easy with their kids.

Get the Perfectly Boring Workbench Plans at Etsy for $5.99

15. Free Workbench Plans

Even beginners can tackle this set of DIY plans for a basic workbench. The simple design serves its purpose without any real flaws. The workbench has four caster wheels that can be locked in place to ensure the workbench doesn’t move while you are cutting or drilling. In addition, these plans are free, so you only need to worry about paying for the material, having the right tools, and putting the work in to make this workbench the newest addition to your workshop.

Get the Easy-Build Workbench Plans at Kreg for Free

16. Workbench Plans for Kids

Hobbyists can construct this innovative workbench to introduce woodworking and DIY to their kids. Despite the small size, this workbench is made with a thick, hardwood butcher block and features built-in LED lighting to show off the toy tools hung on the metal pegboard organizer. Build this workbench for a child’s holiday or birthday gift.

Get the Kids Workbench Plans at Etsy for $7

The prices listed here are accurate as of 10/31/23.