We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Circular saws typically include a standard blade for general-purpose work. Although these blades work well to crosscut 2x4s or rip through softwood boards, the finish quality may not be great. Changing the blade to a product made for the job at hand usually improves both speed and precision. However, with hundreds of different blades on the market, selecting the right one may prove challenging. The following guide contains the information necessary to choose the best circular saw blade for any task.

- BEST OVERALL: Freud D0740A Diablo 7-1/4 Finishing Saw Blade

- BEST BANG FOR THE BUCK: IRWIN Tools MARATHON Carbide Circular Saw Blade

- BEST FOR FRAMING: BOSCH DCB624 Daredevil Circular Saw Blade

- BEST FOR PLYWOOD/OSB: CRAFTSMAN 7-1/4-in 140-Tooth Circular Saw Blade

- BEST FOR MELAMINE/VENEER: Freud 7-1/4″ Ultimate Plywood and Melamine Blade

- BEST FOR NONFERROUS METAL: Oshlun SBNF-072560 7-1/4-Inch 60 Tooth TCG Saw Blade

- BEST FOR STEEL: IRWIN 7-1/4-Inch Metal Cutting Circular Saw Blade

- BEST FOR SIDING AND PVC: Century Drill & Tool Cenalloy Circular Saw Blade

- BEST FOR MASONRY: DEWALT Diamond Blade for Block and Brick, Dry/Wet

- BEST FOR FIBER CEMENT: Freud D0704DH Diablo 7-1/4″x4T PCD Tip TCG

Types of Circular Saw Blades

A circular saw is an easy-to-use, versatile tool, and even the best cordless models are not particularly expensive. Because the blades change out quickly and easily, much of their versatility comes from the large variety of blades available. With the right blade, one tool can cut very different materials, from lumber to sheet metal.

Wood

Woodcutting is perhaps the most popular use for circular saws. Specific options exist for cutting plywood or OSB, for example, and some blades are designed especially for framing and roofing. Other blades create a smooth finish on hardwoods that doesn’t require sanding.

Metal

Metal-cutting circular saw blades cut two kinds of metals: nonferrous, which are “soft” metals that don’t contain iron, such as aluminum, copper, and brass; and ferrous metals, which include various types of steel. Ferrous metals are very hard, so a ferrous blade can cut nonferrous metals, but a nonferrous blade cannot cut steel. Attempting to do so is dangerous.

Masonry and Other Materials

Some circular saw blades are designed specifically to cut concrete, tile, composite board, plastic siding, fiber cement, and other materials. These blades often have a rim encrusted with industrial diamonds instead of sawteeth.

The size of a circular saw limits the depth of the cut, but blades are available to cut almost any type of material. These blades typically provide performance benefits over standard blades at a modest cost.

What to Consider When Choosing the Best Circular Saw Blade

At first glance, circular saw blades might appear simple. Not required to cut curves or composite angles, they’re designed for straight cuts or occasional bevels. However, blades are manufactured to different specifications, which affect performance.

Size of Blade and Kerf

Blade diameter and arbor size (the hole in the center of the blade that fits over the drive shaft of the tool) determine whether a blade will fit a particular saw. Blades measuring 7¼ inches and 6½ inches are the most common sizes, but compact models can use blades as small as 3 inches. In most cases, it’s OK to use a slightly smaller blade (for example, a 7-inch blade on a 7¼-inch saw), but always check the manufacturer’s recommendations. Some arbors have a diamond-shaped edge to prevent the blade from slipping, called diamond knockout blades.

Kerf is the width of the material removed by a saw blade, which normally is the same as the widest part of the teeth that extend beyond the body of the blade. Kerfs are described as “full,” “thin,” and “ultra-thin.” Circular saw blades are invariably thin or ultra-thin, which reduces the weight, puts less strain on the motor, and uses less energy.

Blade Material and Coating

The main part of the blade is usually made from high-carbon steel (HCS) or high-speed steel (HSS), both of which offer excellent strength and durability. However, both are susceptible to rust, so the manufacturer usually applies a coating, which also helps prevent the buildup of resins when cutting softwood and reduces friction.

Friction is important because overheated blades can warp. A more effective method of prevention is to cut expansion slots (also known as stabilizer vents) in the body of the blade.

On some blades, the teeth are cut directly from the body, and they might be hardened more to stay sharp longer. However, on most blades, tungsten carbide tips are added. Carbide is a ceramic powder that compresses into extremely hard “chips” that retain their cutting edge longer, which also helps disperse heat better.

Number of Teeth and Tooth Grind

Generally, a blade with a low tooth count cuts rapidly, whereas a blade with a high tooth count creates a smoother finish. However, the material itself has a big impact. Sawdust is much larger than swarf (metal particles), so a wood-cutting blade must have fewer teeth to clear the waste and avoid binding in the cut. Metal particles are finer and metal is harder, so a blade must present more cutting edges in quick succession to cut effectively.

A general-purpose woodcutting blade may have around 24 teeth, while a metal-cutting blade can have 60 teeth or more. However, exceptions exist; for example, melamine is a fragile surface, so a high tooth count is advised.

Tooth count is only part of the equation, however. Tooth grind—the shape of the cutting edge—can be equally important. Alternative top bevel (ATB) and Hi-ATB blades, which are used for woodcutting, are the most common. The sharpened edge is on the left side, then on the right, on each consecutive tooth.

The term “flattopped” is self-explanatory, and it’s an aggressive style usually reserved for ripping sheet material. Triple-chip grind (TCG) uses a flattop tooth, then a pointed tooth, and so on. These are frequently found on plastic- and metal-cutting blades.

Safety Tips for Using the Best Circular Saw Blade

Find a quick guide to basic circular saw safety here, and check this section for safety advice pertaining to the blades.

- Never use a circular saw blade for any purpose other than that recommended by the manufacturer. Don’t try to use a wood blade on metal, for example. The stresses involved can, at the very least, lead to poor performance, but in extreme cases, cause blade fracture. Since blades can rotate in excess of 5,000 rpm, this could be very dangerous.

- Before using the saw, check that the arbor nut is tight and that the blade doesn’t wobble.

- “Ring” the blade with the knuckle of your index finger. Listen for a clear tone; if it sounds dull, the blade might be cracked.

- Never use a damaged blade or one that might be damaged. A few chipped teeth might not look serious, but if they break while using the blade, they can cause serious injury.

- Never work without the blade guard in place.

- Always disconnect the power source (cord or battery) when changing the blade.

Our Top Picks

These top picks demonstrate the wide choices available in the best circular saw blade. From leading brands, they offer both high quality and good value.

Best Overall

Freud D0740A Diablo 7-1/4 Finishing Saw Blade

Pros

- High-quality, precision manufacture

- Excellent durability

- Smooth, finished cut

Cons

- Modest material range

- Slightly more expensive

Product Specs

- Diameter: 7¼ inches

- TPI: 40

- Recommended for: Softwoods and hardwoods

Many people, particularly DIY users, simply want a high-quality, general-purpose blade, such as this Freud D0740A product. This blade is part of the Diablo line, which feature a corrosion-resistant, low-friction coating. ATB teeth, which are made from Freud’s own carbide formula, include cobalt for extended wear resistance.

The kerf on the blade is described as “thin.” Expansion slots help keep the blade cool and control movement. This all-purpose saw blade won’t cut quite as quickly as a similar 24-tooth blade, but the difference is minimal. The upside is a smooth finished cut that often requires no further planing or sanding.

Best Bang for the Buck

IRWIN Tools MARATHON Carbide Circular Saw Blade

Pros

- Fast cutting

- Good durability

- Good value, especially as a standard general-purpose blade

Cons

- Leaves a slightly coarse finish

- Doesn’t cut hardwood well

Product Specs

- Diameter: 7¼ inches (a 6½ inch is available)

- TPI: 24

- Recommended for: Softwoods (particularly dimensioned lumber)

IRWIN Tools says they chose the Marathon name to emphasize that the blades are “long-distance runners.” The tooth pattern, which combines one standard ATB followed by a thinner version, offers especially rapid cutting.

Speed is also enhanced by a thin kerf, a silicon coating that resists the buildup of resin, and cooling vents that ensure blade stability. Regardless of speed, the blade offers excellent performance for the jobs that many DIYs tackle, such as cutting fencing or decking boards.

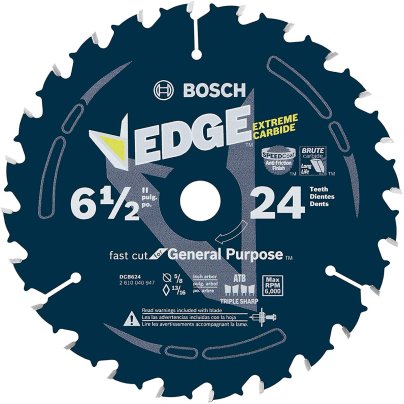

Best for Framing

BOSCH DCB624 Daredevil Circular Saw Blade

Pros

- Designed for job site durability

- Rapid cutting

- Affordable specialty blade

Cons

- Leaves relatively coarse finish

Product Specs

- Diameter: 6½ inches

- TPI: 24

- Recommended for: Softwood, plywood

A framing blade is usually designed for rapid cutting of dimensioned lumber and other softwoods, and the BOSCH DCB624 focuses on framing. These blades are not the blade for making fine furniture: Speed is more important than finish quality in framing, because the resulting cut usually is hidden.

The BOSCH Daredevil has an ATB tooth grind, the optimal choice for fast ripping and cross-cutting. A substantial amount of material is behind each tooth, which, in addition to BOSCH’s proprietary Brute Carbide, provides strength and high-impact resistance.

The blade contains a low-friction coating that resists overheating and helps prevent blade distortion, key features in a blade that must cut for long hours every day.

Best For Plywood/OSB

CRAFTSMAN 7-1/4-in 140-Tooth Circular Saw Blade

Pros

- Minimal tear-out in multilayered materials

- Clean cutting of plastics

- Low cost

Cons

- Average durability

- Can warp if overheated

Product Specs

- Diameter: 7½ inches

- TPI: 140

- Recommended for: Plywood, OSB, plastics, PVC

Plywood is made from consecutive layers of wood fiber at 90 degrees of each other, so a circular saw blade for plywood must rip and crosscut at the same time, making it quite difficult to cut cleanly. Tear-out—ragged, broken fibers—is often a problem.

Carbide teeth with steep profiles are one solution, and this CRAFTSMAN blade presents another. The 140 teeth punched out of the main body are both effective and quite affordable. A high tooth count is also ideal for cutting most plastics.

The blade’s high-carbon steel is hardened to improve durability, though it remains modest. While overheating is seldom a problem with plywood, the blade contains no vents or expansion slots, so it may warp. Allowing the blade to cool periodically should prevent warping.

Best for Melamine/ Veneer

Freud 7-1/4" Ultimate Plywood and Melamine Blade

Pros

- Exceptional quality

- Long working life

- Good versatility

Cons

- Expensive

- Not for softwoods

Product Specs

- Diameter: 7½ inches

- TPI: 60

- Recommended for: Melamine, laminates, veneered composites, plywood

Melamine is a tough plastic, usually bonded to a particle board or MDF core. It provides a durable, waterproof, stain-resistant surface ideal for kitchen worktops; however, like other veneered boards and laminates, it’s difficult to cut without chipping.

A blade with lots of teeth and fine cutting angles slices quickly through the outer surface. The 60-tooth Freud Ultimate uses a steep, Hi-ATB profile, along with their own TiCo carbide, which includes titanium and cobalt to produce razor sharp edges. Their Perma-Shield coating reduces blade resistance to help cut through dense materials.

This blade also can produce a smooth finish on hardwoods, especially when crosscutting, so while it’s among the more expensive circular saw blades, it’s versatile.

Best For Nonferrous Metal

Oshlun SBNF-072560 7-1/4-Inch 60 Tooth TCG Saw Blade

Pros

- Teeth designed for performance and durability

- Heat vents prevent blade distortion

- Minimal burring of cut edges

Cons

- Not for ferrous metals

- Relatively costly for a material-specific blade

Product Specs

- Diameter: 7¼ inches

- TPI: 60

- Recommended for: Aluminum, brass, bronze, copper

Cutting metals with a saw often leaves a burr, which is a razor-sharp edge that must be removed with a file or abrasives. This Oshlun saw blade’s tooth profile is designed to dramatically reduce burr, often requiring no additional work from the user.

The company states that the blade’s teeth are made of a “specially formulated” carbide. The teeth also have a negative rake (they don’t point forward like most blade teeth), which makes them very strong. This helps resist the high-impact forces involved and ensures durability. Vents on the blade prevent overheating.

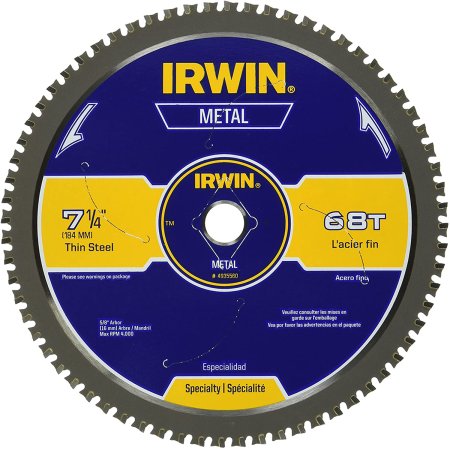

Best For Steel

IRWIN 7-1/4-Inch Metal Cutting Circular Saw Blade

Pros

- Precision engineered for stability

- Cools quickly, so doesn’t distort

- Produces minimal sparks

Cons

- Finish might require further work

- Not suitable for cutting rebar

Product Specs

- Diameter: 7¼ inches

- TPI: 68

- Recommended for: Steel sheet, metal roofing panels, nonferrous metals

Steel is the toughest material a circular saw can cut, but its hardness limits the thicknesses a blade can handle. However, with the right blade, users can still tackle a wide range of construction and engineering applications.

This 7¼-inch circular saw blade from IRWIN is a steel-cutting blade that follows the same principles as the Oshlun nonferrous version. The teeth have a negative rake and a deep body to resist severe impacts. A high tooth count means the saw can present a nearly continuous cutting edge.

The blade body is precision made, with anti-vibration vents that minimize movement and allow straight, accurate cutting. The carbide teeth’s anti-kickback design prevents the saw from jumping away from the cut. The teeth do a good job of minimizing swarf (metal debris) and produce few sparks.

Best For Siding and PVC

Century Drill & Tool Cenalloy Circular Saw Blade

Pros

- Leaves a smooth finish

- Cuts rapidly

Cons

- Modest durability

- Limited material range

Product Specs

- Diameter: 7¼ inches

- TPI: 120

- Recommended for: Vinyl siding, PVC pipe, and gutters

Because their teeth are comparatively large, most general-purpose circular saw blades are too aggressive for vinyl siding, because they leave a rough edge and may split the panels. PVC pipe is more forgiving, but large teeth can skate across the surface, making the saw difficult to manage.

This Century Drill & Tool blade is designed specifically to solve these problems. It has a very high tooth count, so the saw can present lots of small teeth in quick succession. The teeth bite the material rapidly, resulting in efficient cutting and a smooth finish.

Both blade and teeth are made from the same blank of hardened steel. The steel is much less durable than carbide, though the materials it’s designed to cut are relatively soft. Expansion slots provide good blade stability.

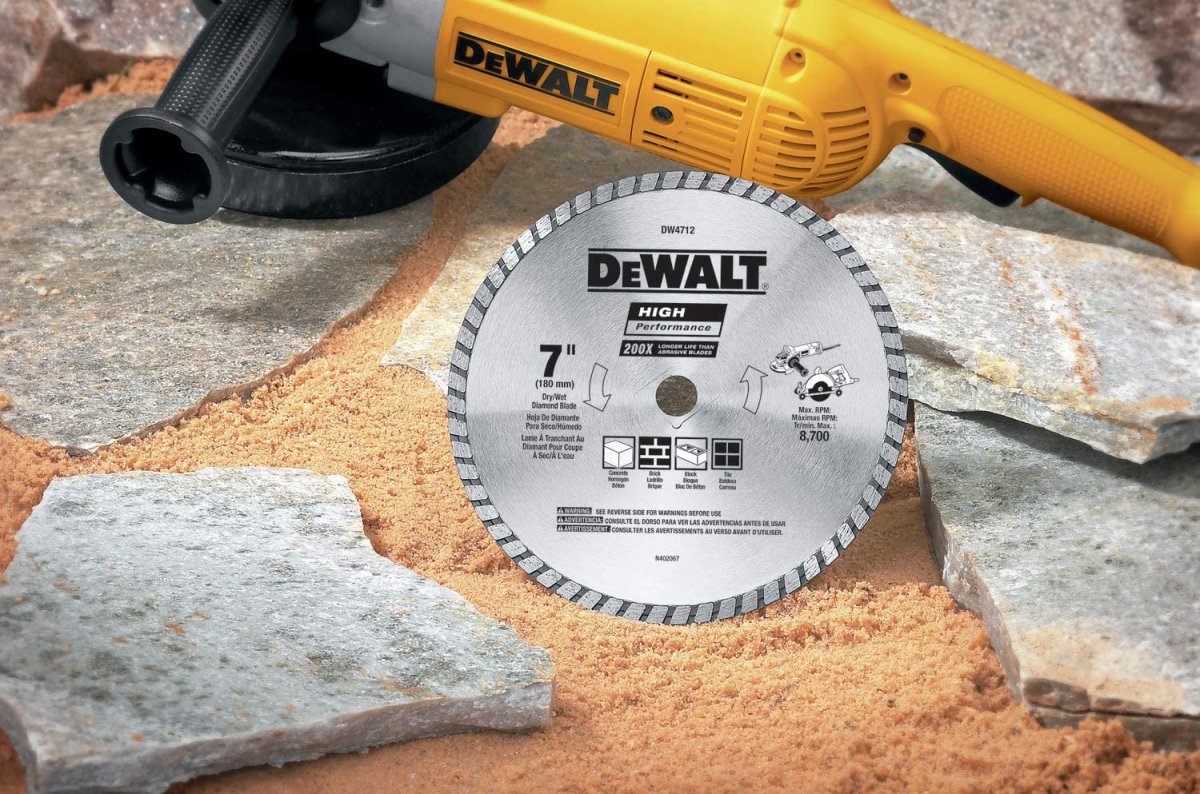

Best For Masonry

DEWALT Diamond Blade for Block and Brick, Dry/Wet

Pros

- Rapid cutting

- Low dust

- Can also be used in angle grinders

Cons

- Specialty blade for masonry only

Product Specs

- Diameter: 7 inches

- TPI: Not applicable

- Recommended for: Concrete, brick, block, tile

A sectional or continuous rim, such as the one on this DeWalt Diamond Blade, works best to cut concrete, brick, and ceramics. The blade’s edge is encrusted with industrial diamonds.

This DeWalt product is a 7-inch blade designed to fit 7¼-inch circular saws. Similar in appearance to the abrasive wheel used with angle grinders, this model is sturdy enough for dual-purpose use. It has a thin kerf, which supports accuracy in cutting and reduces the amount of dust.

Note: OSHA (Occupational Safety and Health Administration) warns against exposure to concrete dust. Always wear respiratory protection when cutting this type of material.

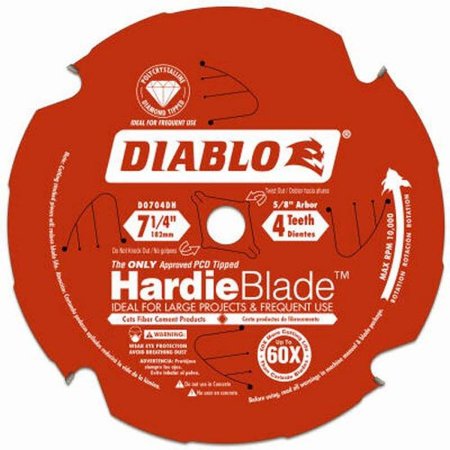

Best For Fiber Cement

Freud D0704DH Diablo 7-1/4"x4T PCD Tip TCG

Pros

- Rapid, accurate cutting of fiber cement

- Exceptional durability

- Minimal dust

Cons

- Cuts fiber cement only

- Expensive

Product Specs

- Diameter: 7¼ inches

- TPI: 4

- Recommended for: Fiber cement

A popular construction material, fiber cement is tough, durable, and attractive. However, it’s difficult to saw and requires a specialty blade like this Diablo from Freud. This model has been approved by James Hardie Industries, the world’s largest manufacturer of fiber cement products.

The carbide teeth are tipped with polycrystalline diamond (PCD), which, along with the triple-chip tooth profile, produces a blade that Freud reports lasts 60 times longer than carbide alone. The Freud fiber cement blade has low-friction coating and expansion slots to ensure stability.

Note: Always wear respiratory protection when cutting fiber cement.

Our Verdict

Freud is a recognized industry leader, and Freud’s 40-Tooth Diablo blade, which offers unrivaled quality and fast, clean cutting, is a top general-purpose circular saw blade. The IRWIN Tools Marathon blade is a quality budget choice, ideal for a variety of yard and remodeling jobs.

How We Chose the Best Circular Saw Blades

As a trained engineer who also has renovated two houses, I have firsthand knowledge as to how circular saw blades should perform when cutting a variety of materials. After noting blade diameter and arbor size, I checked the number of teeth and grind in particular, as these have the biggest impact on performance.

Manufacturer reputation also plays a part in choosing the best circular saw blades. Certain brands have established themselves as leaders in the market, consistently producing high-quality blades, which virtually guarantees performance. However, I’ve been careful to offer several quality alternatives and to include value-for-money options when appropriate.

FAQs

These sections cover the important technical aspects of buying a circular saw blade, followed by a wide range of high-quality examples to choose from. Next, find answers to some of the most common questions that arise concerning the day-to-day use of circular saw blades.

Q. How do I change a circular saw blade?

First, unplug it or disconnect the battery. Find the arbor lock button to stop the blade from rotating, and press it down. Use the provided blade wrench to release the arbor nut. Lift the blade guard to remove the old blade. Place the new blade over the arbor, replace the nut, and tighten.

Q. How do I clean a circular saw blade?

Unplug the saw, remove the blade, and place the blade in a bowl or tray. A variety of general-purpose cleaning solutions are available, but a 50/50 solution of water and laundry detergent is a popular choice. Remove stubborn spots with a toothbrush. Don’t use oven cleaners; they can harm tungsten carbide.

Q. Are circular saw blades interchangeable between brands?

Absolutely. If the diameter and arbor size are correct, you can use any brand you prefer.

Q. What is the difference between a circular saw blade and a miter saw blade?

Circular saw blades are usually smaller in diameter. Most miter saw blades measure 10 to 12 inches, while circular saw blades typically measure 7¼ or 6½ inches. Miter saws are generally used for wood, plastics, and, occasionally, for nonferrous metals, but rarely for steel or masonry.

Q. Which saw blade makes the smoothest cut?

The more teeth a circular saw blade has, the smoother the cut. However, the tooth grind should be appropriate for the material you’re sawing.

Q. How long do circular saw blades last?

Blade life varies considerably because it depends on the material you’re cutting, the quality of the blade, and its frequency of use. A professional could wear out a blade in 20 or 30 hours, but an occasional DIY user might use the same one for years.

Q. Is it worth sharpening circular saw blades?

Many low-cost circular saw blades are treated as disposable, but high-quality products are worth resharpening. However, sharpening carbide blades is a specialist job, so you will need to find a local service.

Q. Can a 7¼-inch circular saw cut a 4×4?

No. Although 4×4 dimensioned lumber actually measures only 3½ by 3½ inches, a 7¼-inch saw has a maximum cut of about 2½ inches. Thus, it can cut a 2×4, but not a 4×4.