We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Dovetail jigs are indispensable when it comes to cutting matched pieces of corner joints for woodworking projects. They clamp workpieces in place, allowing users to run a router along a cutting template to create an interlocking joint that looks like a series of bird’s tails. Dovetail joints are very strong and stable with plenty of surface area for gluing. A dovetail router jig makes it possible to create perfect dovetail joints time and again. But these tools can be quite expensive, and not all are easy to use. So we did the research to find which options professional and amateur woodworkers preferred, then tested four of the most popular dovetail jigs on the market.

The Porter-Cable Deluxe Dovetail Jig was our favorite. It is not the cheapest option, but it is very well built, accurate, and comes with an assortment of templates to make different kinds of dovetail joints, so it’s our first choice overall. Many readers may find one of the other, simpler models we tested better suited to their needs. In this review, we will share our observations from testing four of the best dovetail jigs on the market, detail a few other great options that we didn’t get to test, and highlight the essential shopping considerations to help you choose the right one for your shop.

- BEST OVERALL: Porter-Cable 4216 12-Inch Dovetail Jig Kit

↓ Jump to Review - BEST BANG FOR THE BUCK: General Tools 861 E-Z Pro Dovetail Jig

↓ Jump to Review - BEST FOR BEGINNERS: Rockler 22818 Complete Dovetail Jig

↓ Jump to Review - BEST FOR ROUTER TABLE: Leigh RTJ400 Router Table Jig

↓ Jump to Review - BEST FOR HALF-BLIND DOVETAILS: Porter-Cable 4210 12-Inch Dovetail Jig

↓ Jump to Review - MOST VERSATILE: Leigh Super12 12-Inch Dovetail Jig

↓ Jump to Review - BEST FOR LARGE PROJECTS: Porter-Cable 4212 12-Inch Dovetail Jig

↓ Jump to Review - BEST FOR SMALL WORKSHOPS: Keller 1500 Journeyman Dovetail Jig

↓ Jump to Review

| Porter-Cable 4216 | General Tools 861 | Rockler 22818 | Leigh RTJ400 | Porter-Cable 4210 | Leigh Super12 | Porter-Cable 4212 | Keller 1500 | |

| Works with | Free router | Free router or router table | Free router | Router table | Free router | Free router | Free router | Free router or router table |

| Joint types | Through dovetail, box, half-blind dovetail, rabbeted dovetail, sliding dovetail, mini through dovetail, mini box joint | Through dovetail, half-blind dovetail, box | Through dovetail, half-blind dovetail | Through dovetail, half-blind dovetail, box | Half-blind dovetail, rabbeted half-blind dovetail, sliding dovetail | Variable through dovetail, half-blind dovetail, sliding dovetail, box | Through dovetail, box, half-blind dovetail, rabbeted dovetail, sliding dovetail | Through dovetail |

| Template material | Aluminum | Aluminum | Phenolic | Aluminum | Aluminum | Aluminum | Aluminum | Phenolic |

| Max material thickness | 1⅛ inch | 1 inch | 1⅛ inch | 1 inch | 1⅛ inch | 1 inch | 1⅛ inch | ¾ inch |

| Max material width | 12 inches | Unlimited | 11 inches | 16 inches | 12 inches | 12 inches | 12 inches | Unlimited |

Our Top Picks

Different woodworking projects have different needs, so we tested four highly-rated models in our search for the best dovetail router jigs. Whether you need a heavy-duty jig with the widest range of settings, a budget-friendly tool that is easy to use and store, or absolute repeatable precision, one of these models is sure to work for you.

Best Overall

Porter-Cable 4216 12-Inch Dovetail Jig Kit

What We Like

- Works with large- and small-dimension material

- Outstanding functionality for the price

- High-quality construction

- Lots of joinery options

- Accurate and repeatable results

What We Don’t Like

- Requires dedicated workshop space

- Adjustments require attention to detail

Specs

- Maximum board width 12 inches

- Maximum board thickness 1⅛ inch

- Types of joints Through, half-blind, rabbeted and sliding dovetail, box, mini through dovetail, mini box

Our Ratings: Ease of Use 4.7/5; Build Quality 5/5; Value 4.7/5

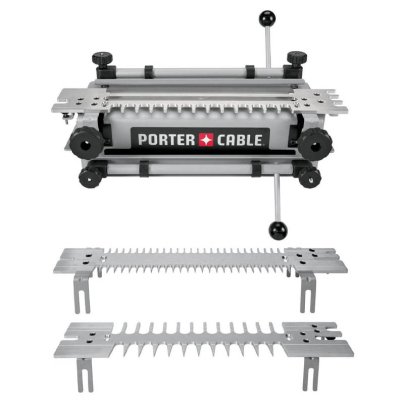

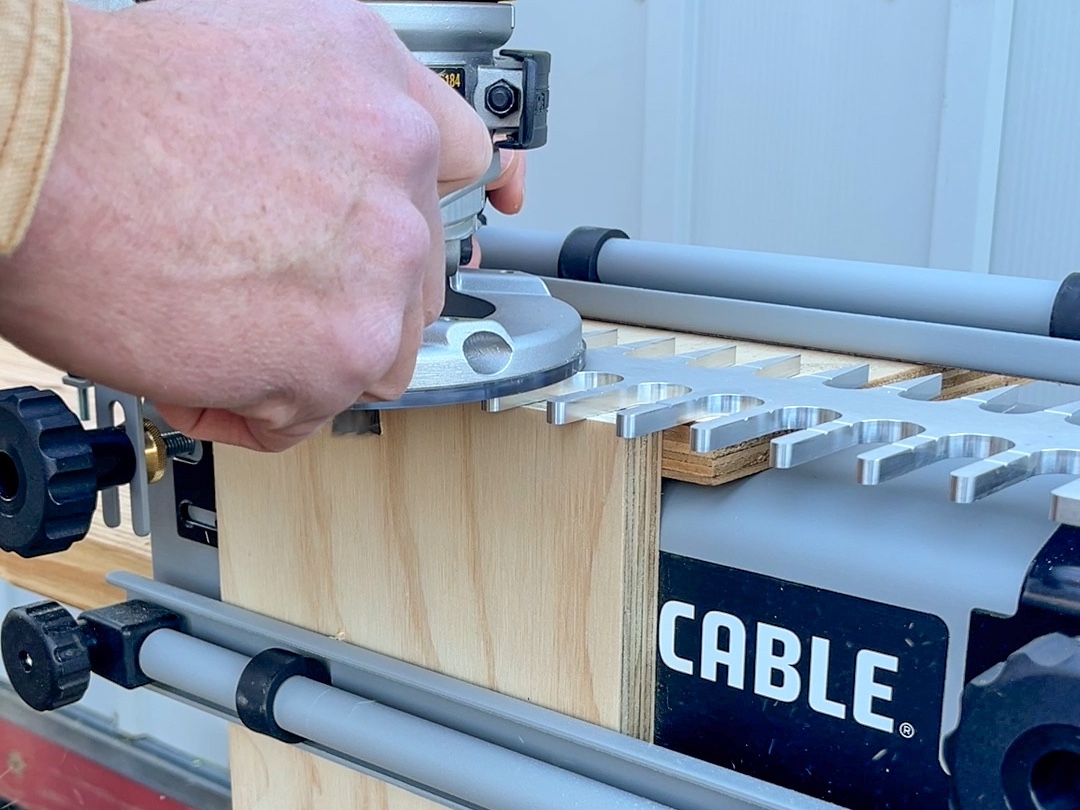

When it comes to build quality, accuracy, consistency, and convenience, the Porter-Cable 4216 deluxe dovetail jig checks all the boxes. This kit includes the bench-mount jig body, three heavy-duty milled aluminum templates, four professional-quality router bits, and router guides. It’s everything you need to create most dovetail sub-types in workpieces up to 12 inches wide and 1⅛ inch thick.

This Porter-Cable 12-inch dovetail jig includes aluminum templates for half-blind, rabbeted half-blind, through, and sliding dovetails, as well as box joints and a mini dovetail/box joint jig. Adjustable edge guides ensure consistently accurate board placement, and sandpaper-backed cam-type clamps quickly secure boards in place. The jig also includes built-in adjustable router bit depth stops to eliminate measurement errors.

Although the Porter-Cable 4216 kit appeared fairly complex at unboxing, we found the instructions mostly clear. After reading the manual and watching a couple of short user videos, it only took about 15 minutes to assemble and adjust the jig and set up our router to start cutting. The results could not have been better—a perfect through dovetail joint on the first try. We ended up trying out all three of the reversible templates, and made joints with woods of both equal thickness and unequal thickness. Resetting the jig required close attention to several critical details, but following the directions each time led to nice snug joints.

What our tester says: “The Porter-Cable dovetail system has a lot of moving parts, which made it a little intimidating at first. So I took the time to thoroughly read the instructions, and I got perfectly matched dovetails every time.” —Mark Wolfe, product tester and writer

Get the Porter-Cable 4216 dovetail jig at Amazon, Woodcraft, or Rockler.

Best Bang For The Buck

General Tools 861 E-Z Pro Dovetail Jig

What We Like

- Budget-friendly price

- Compact, easy to store

- Durable milled aluminum jig

- Simple clamp-on assembly

- Works with freehand router or router table

What We Don’t Like

- Achieving consistent accuracy may take practice

- Awkward to clamp the jig/workpiece assembly for cutting

Specs

- Maximum board width Unlimited

- Maximum board thickness 1 inch

- Types of joints Through and half-blind dovetails, box joints

Our Ratings: Ease of Use 4.5/5; Build Quality 4.5/5; Value 5/5

For a compact and affordable approach to dovetails, check out the E-Z Pro dovetail jig from General Tools. Just attach it to the board and use a router table or handheld router with the included top-bearing dovetail router bit to follow the template. The jig fits boards of any width, and the open-ended design and alignment tool make repositioning simple. The maximum width it can handle without repositioning is 6 inches.

This kit comes with the jig and ¼-inch shaft router bit—a nice touch for such an affordable model. Screw-down clamps are built into the jig for clamping securely onto the board. While it doesn’t have additional templates, the jig does offer an effective way to create dovetail and box joints on boards of any width.

The General Tools dovetail jig worked as designed in our tests, which made it an effective and very affordable option for limited use on smaller projects. Following the included directions and a couple of video tutorials, we made nice tight dovetail joints with it. But we discovered that working with the clamp system requires some caution to prevent marring the wood surface. Using this jig with a router table worked best for us. With a handheld router, the assembled jig and board had to be clamped to a workbench for cutting and the jig’s clamp knobs made that an awkward task.

We liked the small size and the durable single-piece jig and template. It doesn’t require dedicated workshop space and doesn’t take up much space in storage, but it is really best for limited use. Dealing with the dual screw-down clamps for a large project or several wide boards—and being limited to 6 inches of dovetailing per setup—slows down the process compared to wider jigs with cam action clamps.

Get the General Tools dovetail jig at Amazon, The Home Depot, or TEquipment.

Best For Beginners

Rockler 22818 Complete Dovetail Jig

What We Like

- Durable steel bench jig

- Easy assembly and adjustments

- Includes router bits, collet, and guide bushing

- Permanent or portable/semi-permanent installation

What We Don’t Like

- Clearer labeling on the jig would be helpful

- Fewer joint options than our top pick

Specs

- Maximum board width 11 inches

- Maximum board thickness 1⅛ inch

- Types of joints Through and half-blind dovetails

Our Ratings: Ease of Use 4.7/5; Build Quality 5/5; Value 4.3/5

For anyone new to cutting dovetail joints, a simple, sturdy jig can make the job easier. The Rockler complete dovetail jig features a steel frame and phenolic templates for dependable service. The jig can handle through and half-blind dovetails, and the compact design makes it easy to store when not in use. This kit includes the jig, pins and tails templates, three router bits, a collet, and a guide bushing for accurate routing.

We assembled the Rockler jig in a permanent configuration on our workbench for testing. As an alternative solution for smaller shops, the base mounting system makes it easy to attach it to a mobile baseboard. That way the jig can be clamped onto a workbench when needed and stored out of the way when not in use.

The cam-action board clamps made production work fast and easy once we adjusted the jig to the proper settings. Getting the settings right required a bit of trial and error for best results. There were preset locations with visual markers for working with ½-inch and ¾-inch stock, but no positive stops. Unfortunately the keys to the lettered stop marks were printed in the user manual but not labeled on the body of the jig (we made a label for future reference). Additionally, the router bit depth gauge is a visual marker that allows a bit more room for error compared to a hard physical stop; we used a mini square to match the bit depth to the visual guide.

Get the Rockler dovetail jig at Amazon or Rockler.

Best For Router Table

Leigh RTJ400 Router Table Jig

What We Like

- Incredibly accurate with minimum setup

- Supports workpieces up to 16 inches wide

- Kit includes all necessary router accessories

- Crystal clear instruction manual and on-tool prompts

What We Don’t Like

- Not ideal for portable router tables

- Longer workpieces feel less stable compared to a bench jig

Specs

- Maximum board width 16 inches

- Maximum board thickness 1 inch

- Types of joints Through and half-blind dovetail, box joints

Our Ratings: Ease of Use 4.3/5; Build Quality 5/5; Value 4.7/5

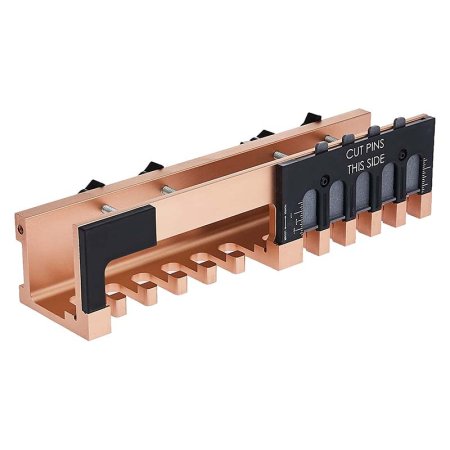

A router table could be the best place to cut through and half-blind dovetails or box joints. The Leigh RTJ400 router table dovetail jig delivers precise, repeatable results with minimal setup time and almost no margin of error. It makes nine sizes of through dovetails, three sizes of half-blind dovetails, and four sizes of box joints. The kit includes a CNC-machined aircraft aluminum base template, adjustable side stops, cam clamps, ½-inch 14-degree and 8-degree dovetail router bits, ½-inch by ⅜-inch and ½-inch straight bits, and a patented elliptical guide bushing.

In many ways, the RTJ400 was the easiest jig we tested. We didn’t need space to mount another tool in the shop, and it held wide and narrow workpieces perfectly steady. The included bit-depth gauge made setting up the router fast and easy. Using a scrap of the workpiece material as a backer, we got clean cuts with no tear out.

After carefully following the setup instructions, the only variable left to adjust was the width of the cut. This is where the elliptical router guide bushing came into play. Because the bushing is not perfectly round, it can be adjusted in 1/1000-inch increments until the pins fit perfectly between the tails. The bushing is indexed so that you can record the setting for later reference and repeat your results.

What our tester says: “The Leigh RTJ400 was incredibly accurate, but it’s probably best for freestanding router tables. We used it with our portable table and stand, which was not ideal for stability and comfort.” —Mark Wolfe, product tester and writer

Get the Leigh dovetail jig at Woodcraft, Lee Valley, Infinity Tools, or Leigh.

More Great Options

With so many options available, it’s possible that one of the jigs we tested may not be right for your dovetail joint woodworking projects. The following recommendations come from our research and hundreds of satisfied users.

Best For Half-Blind Dovetails

Porter-Cable 4210 12-Inch Dovetail Jig

What We Like

- 12-inch capacity

- Solid 1-piece base

- Built-in router bit depth gauge

- Durable aluminum template

What We Don’t Like

- Requires dedicated bench space

- Requires several manual adjustments

Specs

- Maximum board width 12 inches

- Maximum board thickness 1⅛ inch

- Types of joints Half-blind, rabbeted half-blind, and sliding dovetail

This kit features the popular Porter-Cable dovetail jig base assembly plus an aluminum template for half-blind, rabbeted half-blind, and sliding dovetails. The professional quality base and sturdy template make it a reliable option for those with a more limited scope of joinery needs. It’s more affordable than other premium models and takes up less space when not in use compared to the more expansive Porter-Cable kits. The one-piece base assembly mounts on a workbench for complete stability. Quick cam-action clamps secure the workpiece inside a sandpaper-faced bracket. Initial set up and adjustments take a few moments, but once set, the Porter Cable dovetail jig allows for accurate, repeatable cuts and fast production.

Get the Porter-Cable 4210 dovetail jig at Amazon, The Home Depot, Woodcraft, or MSC Industrial.

Most Versatile

Leigh Super12 12-Inch Dovetail Jig

What We Like

- Infinitely adjustable pin and tail spacing

- Creates half-blind, through, and sliding dovetails

- Includes three bits and elliptical template guide

- User-friendly instructions and assembly

What We Don’t Like

- More expensive than other dovetail jigs

Specs

- Maximum board width 12 inches

- Maximum board thickness 1 inch

- Types of joints Variable through dovetail, half-blind dovetail, sliding dovetail, box

DIYers looking for an adjustable dovetail jig for a wide range of through and half-blind joints will want to give Leigh’s Super12 dovetail jig some thought. Most dovetail jigs offer a few different standard patterns, but the Leigh Super12 dovetail jig offers infinitely adjustable pin and tail size and spacing. The jig has a 12-inch capacity, and the adjustable fingers ensure a half pin at the edge of each joint, regardless of board width. For fast, accurate production, an included two-function spacer allows you to precisely offset the tail board and cut pins and tails at the same time.

This jig can be used for through, sliding, and half-blind dovetails. It comes with a special half-blind bridge for guiding the router to improve accuracy, and works with a range of half-blind router bits for custom half-blind joint depths. The kit includes three bits, an elliptical router collar for fine tuning, and a sliding dovetail fence. It’s expensive, but the accuracy and adjustability it offers may be worth the cost.

Get the Leigh dovetail jig at Woodcraft, Lee Valley, or Leigh.

Best for Large Projects

Porter-Cable 4212 12-Inch Dovetail Jig

What We Like

- Large 12-inch capacity

- Includes two aluminum templates

- Cam-action clamps for a fast, firm grip

- Heavy-duty steel base

What We Don’t Like

- Proper adjustments require close attention to details

Specs

- Maximum board width 12 inches

- Maximum board thickness 1⅛ inch

- Types of joints Through dovetail, box, half-blind dovetail, rabbeted dovetail, sliding dovetail

This is the same 12-inch capacity dovetail jig frame as our Best Overall pick, but with only two aluminum templates instead of three: the Porter-Cable 4211 for half-blind, rabbeted half-blind, and sliding dovetails, and the Porter-Cable 4213 for through dovetails and box joints. It’s a reliable option in terms of durability and accuracy, and a more affordable option for those who don’t need the mini dovetail template.

The jig features a one-piece base that must be mounted on a workbench for stability, and cam-action clamps that quickly secure the workpiece, allowing the creation of accurate repeatable joints. The two fixed templates are interchangeable and adjustable for wood thicknesses between ¼ inch and 1⅛ inch. The initial preparation and adjustments take a few moments, but once set, the Porter Cable dovetail jig allows for quick and efficient production.

Get the Porter-Cable 4212 dovetail jig at Amazon, Woodcraft, or Rockler.

Best for Small Workshops

Keller 1500 Journeyman Dovetail Jig

What We Like

- Compact size for workshop or jobsite use

- Includes router bits for dovetails or box joints

- Unlimited capacity for wide boards

What We Don’t Like

- Accurate repositioning requires attention to detail

Specs

- Maximum board width Unlimited

- Maximum board thickness ¾ inch

- Types of joints Through dovetail

Small workshops require compact, flexible tools like Keller’s 1500 Journeyman dovetail jig. The Journeyman is a one-piece kit that DIYers can use to cut through dovetails or box joints. The kit mounts to a strip of wood and measures 15 inches wide, though it’s repositionable for unlimited capacity.

This model comes with two router bits for cutting dovetails or box joints, complete with ball-bearing guides that ride along the template’s plate. While the capacity is limitless, repositioning this jig will require a careful eye to ensure accuracy. However, the benefit of this simple design is that it can sit on a shelf or rack until needed.

Get the Keller dovetail jig at Amazon, Walmart, Woodhaven, or Keller.

Jump to Our Top Picks

How We Chose and Tested the Best Dovetail Jigs

For crafters who build furniture, cabinetry, and artisan boxes, beautiful dovetail joints are a point of pride, but cutting them by hand is very time-consuming. We wanted to source and test router jigs that would make the process faster without adding another layer of problems. After researching the most popular options, we decided to test four that represented a broad range of value and performance. To judge them, we used them as instructed to make through and half-blind dovetail joints in oak, pine, and poplar boards. After two days of cutting and assembling dovetail joints, we recorded our observations on a scoring rubric before assigning the award titles for this review.

| Products tested | 4 |

| Time spent testing | 15 hours |

| Tests performed | 6 |

| Price range | $50 to $440 |

| Porter-Cable 4216 | General Tools 861 | Rockler 22818 | Leigh RTJ400 | |

| Ease of Use | 4.7 | 4.5 | 4.7 | 4.3 |

| Build Quality | 5 | 4.5 | 5 | 5 |

| Value | 4.7 | 5 | 4.3 | 4.7 |

What to Consider When Choosing a Dovetail Jig

Dovetail jigs aren’t new technology, but they’re a less popular and approachable method for joinery than pocket hole jigs. That said, dovetail joints are strong and old-school, though new DIYers might not be familiar with them or know what to look for when shopping. The following sections contain some of the most important factors to consider when looking for dovetail tools.

Material

When choosing the best dovetail joint tool, consider the materials used in each product’s construction. The dovetail jigs of years past were usually cast iron in construction, and if they received regular maintenance, they lasted almost forever. However, they were very heavy and expensive. Today’s models use cast aluminum or steel in their construction.

Dovetail jigs with aluminum parts and templates are light and usually very accurate when making dovetail joints, but they can be expensive. Steel jigs and templates are heavier and less expensive, but they’re also less likely to bend and become inaccurate than an aluminum jig. Unlike aluminum, steel jigs also are susceptible to rust, so it’s best to store them in a dry shop.

One-Step vs. Two-Step

Two types of dovetail jigs are available. One-step jigs usually are a bit more expensive than two-step jigs, but for good reason.

A one-step jig allows users to cut the joint in two boards at the same time. By holding the board ends perpendicular to each other, users can run the router over both boards, perfectly aligning the pins and tails and creating an incredibly accurate joint. Two-step jigs allow users to mill only one board at a time: the board must be unclamped and replaced with the other board, which can introduce room for error.

Fixed vs. Variable Template

Depending on the level of customization needed, users might choose a fixed or variable jig. Each makes robust and reliable joints but with different degrees of customization.

Fixed template jigs use solid templates that create a perfectly uniform joint. Their guides are spaced evenly and consistently. Users can choose from fixed dovetail jigs with different spacing or shapes, but the actual templates are not adjustable.

Variable templates allow users to adjust the spacing, the number of guides, and the look of the dovetail joint. This less uniform look creates a more handmade appearance that many craftspeople appreciate.

Capacity

Before purchasing a dovetail jig, consider the size of the boards each jig can handle. Many jigs can only handle boards of a certain size before they must be removed and repositioned. The more often the boards are repositioned, the more room for error.

For cabinetmaking work, a jig with a 12-inch capacity is usually enough for most drawers. Drawers are rarely deeper than 12 inches, but if they go deeper, some jigs allow the boards to be repositioned to keep milling.

For deeper boxes and crates, many craftspeople prefer a jig with a bit more capacity, such as one within the 24-inch range. These allow the creation of large dovetailed box joints with the router.

Accuracy

When considering the best dovetail jig for router projects, accuracy trumps any other factor. If the dovetail jig isn’t accurate, it will create loose, sloppy joints or worse, joints that don’t fit together at all.

While most jigs have consistent, accurate templates, the quality of the jig itself has a lot to do with the accuracy of the joint. If the jig has lower-quality fittings, clamps, or hardware, things may shift while using the jig. Shifting will create less consistent results. Many of the best options are from trusted brands that use quality parts and hardware made from steel or aluminum.

Types of Joints

As a user’s woodworking journey unfolds and they begin to become better craftspeople, they often appreciate the ability to create a different look or style of joint with a dovetail jig.

Dovetail jigs are useful and fun because they can create so many different types of joints. By swapping out a template, the user can change from making a standard dovetail to a box joint to a half-blind or even a full-blind mitered joint.

Ease of Use

A DIYer probably doesn’t have years of old-school cabinetmaking experience to rely on when setting up a dovetail jig. As a result, most people look for a jig that’s easy to set up and use. Quick-change jigs and quick-grabbing clamps help with setup. Jigs with guides are also available for accurate depth setting, which is an essential measurement for blind and half-blind joints.

Also, consider the ease of cutting joints with the jig. Models that come with swappable router collars allow users to run the router along the guides smoothly, creating accurate joints. Quick lever-activated clamps also help make setup quicker and easier.

Lastly, consider the size and weight of the jig. If the jig is in a dedicated woodworking or cabinetmaking shop, removal and storage aren’t an issue, but most home craftspeople don’t have space to keep the jig up all the time. Older cast-iron jigs were fairly heavy, but today’s models are much more manageable. Remember: the longer the jig, the longer the board it can handle, but the more difficult it will be to store.

Shopping for a Used or Refurbished Dovetail Jig

While there are lots of great dovetail jigs on the market to choose from, it might be worth shopping for a used model. Dovetail jigs have been around for a long time, and the older models were extremely durable. That means there are probably quite a few around, and the deals can be worth the effort.

Many older dovetail kits featured cast-iron construction, making them extremely durable (though a bit heavy). While they may not be adjustable, these jigs are almost sure to be accurate as long as they’re whole and have no missing or bent teeth. And older DIYers or retiring woodworkers looking to get rid of these heavy tools may be willing to pass them on to new craftspeople at heavy discounts.

The downside is that these tools aren’t always readily available on sites like Amazon Renew, ebay Refurbished, or Walmart Refurbished. Due to their weight, they can be cost-prohibitive to ship, though it may be worth checking those sites first anyway. Local yard sales and swap meets may be a better bet.

Tips for Using a Dovetail Jig

If any play or wobble occurs in the jig or workpieces, the results won’t be as accurate. Clamp the jig base securely to the table or the workpiece to ensure the best possible joints.

If the boards come from a home improvement store, be sure to square up their ends before placing them in the router jig. Factory ends are rarely square, and routing them in a dovetail jig will create a box that wobbles or doesn’t assemble properly. Consider running them over a dovetail jointer to ensure that all of the surfaces are perfectly square. If not, a hand plane will do the trick.

Alignment is everything. When clamping the workpiece into the jig, ensure that everything is square and aligned properly. Take your time and make sure that this part of the process is correct. A mistake here can end with a poorly cut joint and two boards that don’t align properly. This step is even more critical when repositioning a jig for a wider board: a small mistake here could keep the joint from coming together at all.

- For consistent results, be sure the jig or workpiece is clamped securely to the table.

- Square the ends of the boards before milling them on the jig.

- Ensure accurate alignment, especially when repositioning the jig on a wider board.

FAQs

Now that you know a bit more about the best-rated dovetail jigs, other questions may arise. Below is a collection of some of the most frequently asked questions about these woodworking tools and their answers. If you still have questions after this, a manufacturer’s customer representative customer service department may help.ilable for helping cut dovetails, other questions may arise. Here, find a collection of some of the most frequently asked questions about dovetail jigs and their answers. If you still have questions, a manufacturer’s customer representative customer service department may help.

No, experience isn’t necessary, but it’s important to realize that small mistakes can result in ruined joints. Taking the time, aligning the workpieces, and ensuring that everything is stable on the workbench can all help achieve excellent results.

Lapped dovetail joints are popular in cabinetmaking. These joints look like standard dovetails; however, the dovetails don’t extend all the way through one of the pieces. This makes the dovetails hidden from one side of the joint.

The dovetails in a full-blind joint are just like standard dovetails, but they don’t pass all the way through. They aren’t visible from any side of the joint. The dovetail pins hide inside the joint and provide a strong joint with lots of glue surface.

Comparing strength in dovetail joints comes down to several different variables, including the size of the dovetails and even the strength of the wood. However, comparing dovetails to box joints and other lap-style joinery almost always shows that dovetails are the strongest.

The possibilities are endless, but a dovetail jig can create dovetail, hidden dovetail, through dovetail, sliding dovetail, mitered dovetail, and box joints, just to name a few.

For most woodworking projects, a 2 horsepower router that accepts both ½-inch and ¼-inch collets will cut most dovetails cleanly and accurately. To ensure quality cuts, opt for the best wood router you can find.

The thickest dovetail jointed boards are usually no greater than 1 inch, so the jig should open to at least that thickness, perhaps as thick as 1⅛ inch.

The joint should be snug, but not so tight that the glue is forced out when the joint is assembled. If you can dry-fit the joint easily by hand (not with the aid of a mallet), and there is no play, it’s about right.

Dovetails should be cut at an angle between 15 degrees and 7 degrees depending on the type of wood—lower angles for hardwood and higher angles for softwood.

Well-made dovetail joints are strong and durable, but they can be difficult to mark and cut accurately. Even when using a router and dovetail jig, there are multiple variables that must be coordinated to create a joint that fits together properly.

Meet the Tester

Mark Wolfe is a writer, product tester and serial DIYer who lives in an older home. When he isn’t writing, he spends his time upgrading, repairing, and replacing anything and everything in his home, yard, and garden. He tests and writes reviews about hand and power tools, lawn care and home repair products, and outdoor living goods.

Additional research provided by original writer Tom Scalisi.