We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Epoxy resin is highly durable and nonporous, making it an ideal choice for a variety of projects. Sealing floors or countertops, creating jewelry, making river tables, and designing resin art are just a few of the numerous ways to use epoxy resin.

Two liquids, a resin and a hardener, are mixed to create epoxy resin. After a few hours, the mixture hardens, which results in a sealed and durable finished product. The best epoxy resin depends on your specific needs; different products on the market are more suitable for certain applications than others. For example, epoxy resin for garage floors and making jewelry require slightly different products, which we take a look at in our list of recommendations.

Keep reading for tips that can help you choose the right epoxy resin for your planned projects. Plus, some of the top-performing epoxy resins are listed below.

- BEST OVERALL: Naked Fusion The Artist’s Resin 1-Gallon Kit

- BEST BANG FOR THE BUCK: Nicpro 16-Ounce Crystal Clear Epoxy Resin Kit

- BEST FOR RIVER TABLES: FGCI Liquid Glass Deep Pour Epoxy

- BEST FOR WOOD FURNITURE: TotalBoat Table Top Epoxy

- BEST FOR RESIN ART: Puduo Epoxy Resin Kit for Art

- BEST FOR JEWELRY: Dr. Crafty Clear Epoxy Resin Kit

- BEST FOR KIDS CRAFTING: ArtResin Epoxy Resin

- BEST FOR GARAGE FLOORS: Rust-Oleum EpoxyShield Garage Floor Coating

How We Chose the Best Epoxy Resins

There are many different features to consider when selecting the best epoxy resins. However, the main factors that were explored during extensive product research include the curing time of the epoxy resin, durability factors like UV resistance and anti-yellowing, and the intended purpose or use of the product.

Casting epoxy resin for creating jewelry, molds, and miniatures isn’t necessarily subject to the same conditions as epoxy resin used for coating applications, so these differences were taken into consideration when determining the suitability and functionality of the products.

Our Top Picks

This list includes some of the best epoxy resin products selected for outstanding product efficacy, as well as important product factors like durability, curing time, toxicity, and viscosity. Organized by project type, one of these may be the perfect choice when it’s time to buy epoxy resin to complete your next project.

Best Overall

Naked Fusion The Artist’s Resin 1-Gallon Kit

Pros

Cons

Product Specs

- Durability: UV light-resistant and heat-resistant to 145 degrees Fahrenheit

- Working time: 45 minutes

- Curing time: Up to 72 hours

Naked Fusion refers to this epoxy resin as “The Artist’s Resin” because it is specially formulated to create a variety of art pieces, including resin art, resin jewelry, river tables, geode paintings, and more. The formula is also suitable for other applications, such as sealing countertops, tables, coasters, and cutting boards. The crystal clear resin mixes nicely with mica pigments or pastes and can also be paired with alcohol inks to add color to projects.

This epoxy resin is nontoxic and low odor with no volatile organic compounds. Unlike with some other resins, there is no need to worry about inhaling toxic fumes or dealing with an overwhelming smell. It is also self-leveling, making it easy to evenly seal surfaces.

After mixing it with the hardener in a simple 1:1 ratio, this epoxy resin offers a 45-minute working time. While it takes 72 hours to fully cure, additional layers can be added after just 8 hours. This resin is also UV-resistant, BPA-free, and food-safe.

Get the Naked Fusion epoxy resin at Amazon or Naked Fusion.

Best Bang for the Buck

Nicpro 16-Ounce Crystal Clear Epoxy Resin Kit

Pros

Cons

Product Specs

- Durability: UV-resistant and anti-yellowing

- Working time: 30 minutes

- Curing time: 24 hours

Use this crystal clear epoxy resin from Nicpro for jewelry making, crafting, casting figurines, sealing tabletops or other objects, and so much more. This budget-friendly option stays crystal clear when cured to leave a transparent finish on various surfaces. The self-leveling property of the resin makes it easy to seal surfaces neatly and uniformly.

Nicpro epoxy resin also boasts a nontoxic, low-odor, and food-safe formula for use with kitchen and dining items. Mixing the right amount of this epoxy resin with the hardener is simple with the 1:1 ratio of both liquids. It offers a 30-minute working time and cures completely after 24 hours.

Get the Nicpro epoxy resin at Amazon or Nicpro.

Best for River Tables

FGCI Liquid Glass Deep Pour Epoxy

Pros

Cons

Product Specs

- Durability: UV-resistant and anti-yellowing

- Working time: 20 to 30 minutes

- Curing time: Up to 72 hours

This deep-pour epoxy resin kit from FGCI is ideal for river tables and other projects that require a greater thickness than many other products on the market are able to achieve.

Pour it for depths of up to 4 inches, and it should offer superior hardness and heat resistance that prevents damage and warping. The formula is thinner than many other products and includes bubble-releasing attributes that result in clear and bubble-free finished products.

This epoxy resin is also suitable to use for casting art, resin jewelry making, tabletop sealing, and more. It accepts a variety of pigments, including liquid pigments, mica powder pigments, and alcohol inks and dyes. Full curing typically takes close to 72 hours.

Get the FGCI epoxy resin at Amazon or FGCI.

Best for Wood Furniture

TotalBoat Table Top Epoxy

Pros

Cons

Product Specs

- Durability: Scratch-, stain-, and UV-resistant; anti-yellowing

- Working time: 20 minutes

- Curing time: 5 to 7 days

This epoxy resin product from TotalBoat is designed for use on tables, chairs, and other wooden furniture products. It can also be used on metal, stone, ceramic, and concrete tables, bar tops, and countertops.

It has a no-VOC, BPA-free formula that cures with a smooth, glossy finish that is 100 percent waterproof, according to the manufacturer, making it ideal for protecting sensitive wooden surfaces.

This epoxy resin is also resistant to UV radiation as well as scratches and other abrasion damage. While it’s best used as a coating resin, the formula can also be used as a casting resin in order to make resin art, embed objects, and create other crafting projects.

Curing typically takes a few days, and can take up to 7 days for a full cure, though a second coat can be applied just 4 to 8 hours after the initial pour.

Get the TotalBoat epoxy resin at Amazon or Total Boat.

Best for Resin Art

Puduo Epoxy Resin Kit for Art

Pros

Cons

Product Specs

- Durability: UV-resistant and anti-yellowing

- Working time: 45 minutes

- Curing time: 24 hours

Puduo’s epoxy resin offers a variety of features that make it an excellent choice for artists. The resin is crystal clear and designed to provide a lasting finish to a variety of surfaces.

It is ideal for creating resin art, resin jewelry, geode paintings, and river tables, in addition to sealing a variety of other surface types. The kit also comes with other items needed for working with epoxy resin, including gloves, wooden sticks, and mixing cups.

Mixing a simple 1:1 ratio of the resin and the hardener is all that is required to get started. This resin allows for 45 minutes of working time and cures more quickly than many other products on the market. It should fully cure after 24 hours.

Get the Puduo epoxy resin at Amazon or Puduo Family (16 ounces).

Best for Jewelry

Dr. Crafty Clear Epoxy Resin Kit

Pros

Cons

Product Specs

- Durability: Smudge- and UV-resistant; anti-yellowing

- Working time: 40 to 60 minutes

- Curing time: 2 to 3 days

Dr. Crafty’s clear epoxy resin comes as part of a kit with other essential supplies for crafting with resin and helps users start working right away. In addition to the 32-ounce bottles of resin and hardener, this kit also includes two plastic cups, a plastic stirrer, and a plastic spatula.

After curing, this epoxy resin stays clear and does not yellow, making it ideal for crafting jewelry pieces. In addition to being an ideal choice for jewelry making, it is also optimal for other crafting and sealing projects.

The resin offers up to 60 minutes of room-temperature working time. Projects should dry within 24 hours and fully cure within 72 hours. Finished products are UV-resistant, smudge-resistant, and anti-glare.

Get the Dr. Crafty epoxy resin at Amazon.

Best for Kids Crafting

ArtResin Epoxy Resin

Pros

Cons

Product Specs

- Durability: UV-resistant and anti-yellowing

- Working time: 40 to 60 minutes

- Curing time: Up to 72 hours

For those looking for the best epoxy resin for crafts that is safe for use around children, take a look at ArtResin’s clear epoxy resin. This epoxy resin is nontoxic, nonflammable, does not release fumes, and is safe to use in homes with adequate ventilation.

It features a self-leveling and high-gloss formula that resists yellowing, making it an ideal choice for various art projects, such as making jewelry, resin art, woodworking, and more.

This epoxy resin is easy to mix with a straightforward 1:1 ratio of the resin and the hardener. It offers a working time of about 45 minutes and takes about 72 hours to fully cure.

Get the ArtResin epoxy resin at Amazon (8 ounces) or Art Resin (16 ounces).

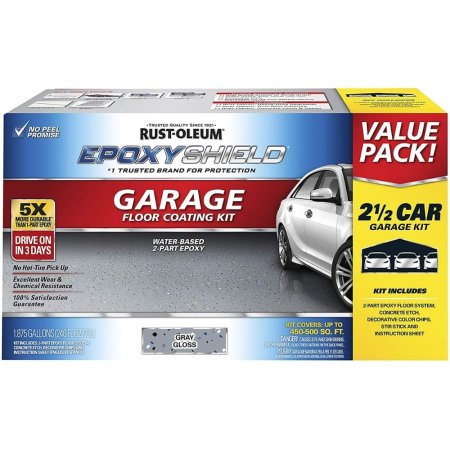

Best for Garage Floors

Rust-Oleum EpoxyShield Garage Floor Coating

Pros

Cons

Product Specs

- Durability: Resistant to UV, chemicals, abrasion, and heat

- Working time: N/A

- Curing time: 72 hours

Rust-Oleum’s EpoxyShield garage floor coating is designed to seal interior concrete surfaces. In addition to being a solid solution to protect garage floors, it is also well suited for basement floors, workshops, and other spaces with concrete floors.

This kit covers up to 500 square feet of surface and is up to five times stronger than a one-part floor paint. Using this epoxy resin on garage floors also offers protection against chemical staining. It allows users to achieve a professional semi-gloss finish without paying a floor-sealing company.

Once it’s mixed, be sure to apply the epoxy resin to floors within 1 to 2 hours. Then, allow it to set for about 24 hours before walking on the surface and about 72 hours before driving on it.

Get the Rust-Oleum epoxy resin at Amazon, Lowe’s, or The Home Depot.

Jump to Our Top Picks

What to Consider When Choosing an Epoxy Resin

Epoxy resin can be used for a variety of different purposes, but every product out there isn’t intended for the same applications. It’s important to understand the material and surface compatibility of a resin epoxy product before making a selection.

Consider the viscosity, curing times, durability, and the other important factors mentioned below in order to find the best epoxy resin for your project.

Material and Surface Compatibility

When deciding on the correct epoxy resin for a project, one of the first things to consider is whether the product will be compatible with the material. Epoxy resin can be used on wood, metal, glass, stone, fabric, ceramic, and even on concrete in order to coat garage, basement, or patio floors.

However, it’s important to check the manufacturer’s directions before purchasing in order to determine the specific material for which the product is made. Otherwise, the project could result in failure.

The surface compatibility is also a factor because epoxy resin doesn’t stick to certain surfaces like painter’s tape, wax, polyethylene plastics, silicone, parchment paper, freezer paper, and anything with a greasy surface. Make sure to clean and prepare the area before applying the epoxy resin for the best results.

Viscosity

The viscosity of an epoxy resin refers to the thickness of the solution before it is applied to a surface. This is different and distinct from the depth and thickness that is achieved after the solution is poured or otherwise applied to a surface. Manufacturers make epoxy resins in a wide range of viscosities in order to provide products that are suitable for an equally wide range of applications.

- High-viscosity epoxy resin is very thick, and it can create a richer, shinier appearance than low-viscosity epoxy resin. However, it takes a long time to apply because the thick viscosity makes it difficult for bubbles to escape, so it must be applied at a slower pace.

- Low-viscosity epoxy resin is thinner, more like a liquid than a gel. While it doesn’t produce the same visual effects as high-viscosity epoxy resin, it can be applied in thicker layers. It is faster and somewhat easier to apply.

Depth and Thickness

Many epoxy resins are designed to only be poured to thicknesses of between 1 and 3 centimeters. This is generally adequate for sealing floors, tables, countertops, and other surfaces, but it may not be ideal for crafting jewelry, filling in river tables, and other projects where more height is necessary.

For those projects that require a thicker coating, deep-pour epoxy resins are available. Deep-pour epoxy resins are specifically made to cure at a slower rate, which allows several layers to be applied for a thicker, deeper pour. These products are great for encapsulating objects or making river tables.

Working and Curing Times

There is a difference between the working time and curing time of an epoxy. It’s important to know both when selecting and using epoxy resin.

- Working time refers to how long an epoxy resin will be fluid enough to manipulate. Most epoxy resins will be fluid for around 45 minutes. Times may vary, so check the manufacturer’s specifications. Also consider the size of the area to be treated; if working over a large surface area, look for resins with working times longer than 45 minutes.

- Curing time is how long it will take the epoxy resin to completely harden and dry. While some epoxy resins may finish curing after around 24 hours, others may need multiple days to cure. This length of time is usually specified by manufacturers, along with working time.

Odor, Fumes, and Toxicity

The chemicals present in epoxy resin products can be harmful in a few different ways. Depending on the product, it may release harmful fumes and irritating odors when the epoxy resin is opened, mixed, and applied.

The epoxy resin may also be dangerous if it gets on skin, so it’s important to always take proper precautions when working with epoxy resin. Work in a well-ventilated location with appropriate safety gear, including gloves, safety glasses, and breathing protection.

However, not all products are highly dangerous. In fact, many epoxy resins are specifically designed to be odor-free, nontoxic, and BPA-free. Check the product information and refer to the manufacturer’s recommendations to find out about the odor and toxicity of a specific epoxy resin.

Durability

After applying epoxy resin and allowing it to cure, the surface should be hard and smooth. However, the durability of the finished product depends on the epoxy resin that was used.

Manufacturers can alter the formula to increase the durability of the product by focusing on UV resistance, abrasion resistance, chemical resistance, and enhanced impact strength.

- UV resistance helps ensure that the cured epoxy resin can be used in sunny locations without worry about harmful UV rays fading the color or damaging the smooth texture.

- Abrasion resistance makes the finished product (such as a cutting board) hard and unlikely to be damaged by abrasive materials like sponges, scouring pads, and even car tires when the epoxy resin is intended for coating garage floors.

- Chemical resistance is typically present in epoxy resins used for painting basement, patio, and garage floors in order to prevent damage from gasoline, antifreeze, motor oil, and salt.

- Impact strength is a feature that refers to the product’s ability to be hit or driven over without sustaining damage. It’s important for coating floors, but also for upgrading or repairing furniture. The higher the impact strength, the more resistant the epoxy resin will be to impact damage.

Application Method

Epoxy resin can be applied to a variety of different surfaces and can be used to create a range of products, so application methods can vary depending on the intended results. For instance, coating a painting or a countertop requires a different application method than casting a resin figurine or embedding objects.

Consider using a foam roller to apply coats of epoxy resin to a flat or angled surface. The roller can help create consistent layers, eliminating the need to work with a bristle brush that is prone to applying epoxy resin in uneven layers.

For casting, carefully clean and prepare the mold before mixing the epoxy resin, then slowly pour the resin from a mixing cup to form even layers and achieve the desired look and texture.

Additional Features

Epoxy resin products are regularly reformulated and improved by the manufacturers to include a range of additional features, such as self-leveling formulas, bubble-release formulas, yellowing resistance, dye kits, and included gloves.

- Self-leveling formulas have a low enough viscosity that they will naturally form a level surface, similar to the way water will automatically level itself when poured into a glass. This makes it much easier to apply in even layers.

- Bubble-release formulas are designed to allow bubbles to move freely throughout the epoxy resin so that any bubbles that form are quickly released.

- Yellowing resistance helps to prevent the dried and cured epoxy resin from yellowing over time due to exposure to UV radiation, humidity, and changing air temperatures. These products remain clear (or dyed) instead of yellowing.

- Dye kits and gloves can be bundled with an epoxy resin product as a value pack so that the user doesn’t need to shop elsewhere for dyes and safety gloves.

Tips for Using Epoxy Resin

Epoxy resin can be used for a wide range of projects and, like paint, the drying, setting, and curing times of different products can vary.

So when you are trying out a new product for the first time, make sure to mix a small amount of the epoxy resin in order to determine how long it takes to dry to the touch, harden, and cure. This will help you avoid mistakes on the actual project.

Also, make sure to store the epoxy resin at a moderate room temperature. If the epoxy resin gets too cold or dry it can hinder the adhesive ability of the product, while very high temperatures can prevent proper bonding.

After applying one coat of epoxy resin, you may find that the finish isn’t thick enough or doesn’t have the right appearance. Check the manufacturer’s directions to find out how long the first coat should dry before a second coat is added.

- Before starting, mix a small amount of epoxy resin to get a better idea of drying, setting, and curing times.

- Store epoxy resin in a room-temperature location and avoid extremely cold or dry places.

- Refer to the manufacturer’s directions to determine how long to wait before applying a second coat of epoxy resin.

FAQs

Epoxy resin can seem like a complicated product to use, but with practice and a substantial understanding of the substance, it may become one of your favorite methods for updating old furniture or making repairs. Continue reading for more information on the best epoxy resin and its many uses.

Q. What is epoxy resin used for?

Epoxy resin has a wide range of uses, including casting resins that are used to make epoxy resin jewelry, molds, figurines, and miniatures, and coating epoxy resins that are best for home repairs, furniture upgrades, and renovations. Use epoxy resin for wood, metal, concrete, fabric, and even glass.

Q. Is epoxy resin safe to use indoors?

Epoxy resin products are safe to use, but when you are mixing epoxy resin and preparing it for application, the fumes can be inhaled and cause inflammation and irritation in the nose, throat, and lungs.

If possible, it’s better to use epoxy resin outdoors or in a well-ventilated area with gloves, safety glasses, and breathing protection.

However, some coating and casting resins are specifically made for indoor use, so when you are buying epoxy resin, look for indications from the manufacturer that the product is safe to use inside.

Q. Is casting resin the same as epoxy resin?

Casting resins are a type of epoxy resin that is great for making jewelry, molds, figurines, and other casting epoxy resin products. Casting resins have a different consistency than coating resin, which is better for coating tables, floors, and other surfaces.

Q. What surfaces will resin not stick to?

Resin can be an incredible adhesive, but there are some surfaces that it won’t stick to, including wax, polyethylene plastics, silicone, painter’s tape, parchment paper, freezer paper, and anything that has a greasy surface.

Q. What is the easiest way to remove epoxy?

The best method for removing epoxy from a wide variety of materials is to apply heat in order to melt epoxy resin components and residues, allowing the epoxy to be peeled or scraped away.

However, substances like acetone can also be used on hard surfaces like wood and concrete to quickly loosen epoxy so it is easier to peel off.

Deirdre Mundorf is a freelance writer who most enjoys writing in the home, family, and pet niches. She graduated with a Bachelor of Arts degree in Elementary Education and a Bachelor of Science degree in Psychology and spent the first 11 years of her career as an elementary school teacher. Deirdre enjoys spending time with her family, cooking, and traveling.