We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

For many years, installing hard tile was regarded as arcane. It was a specialized vocation best left to the gifted few who, with their years of apprenticeship, were masters of the trade.

That perception has changed. Today, chains of retail stores sell only tile and tiling supplies, and most of their customers are homeowners. Tile is now widely used not just in bathrooms but in kitchens, entryways, and other locations in the home and office where durable, water-resistant surfaces are required. Increasingly, the installation is done by novices who want the look of tile but don’t want to pay master-tradesman fees to install it. Their secret? Having the right set of tiling tools to get the job done.

You don’t need a lot of complicated, expensive tools for your tiling project: There’s the tile cutter (it’s essentially a sophisticated version of a glass cutter) that scores and snaps tiles along straight lines. The wet saw makes quick work of cutting large, hard tiles. And the nipper, a cutting tool with jaws, handles, and a pivot, resembles a pair of pliers but allows picking and nipping little bits of tile from a curve or compound cut.

Tiling products also include a notched trowel used to apply the adhesive or mortar on the tile backing board for affixing the tile and a grout float for spreading the mortar that fills the joints between the tiles.

You’ll also need a few other familiar tools, like a tape measure, chalk box, framing square, and a basic carpenter’s level. There’s no need for a laser level. With these tools readily available, tiling is no longer solely the domain of the tilers’ guild.

1. Tile Cutter

Also known as a snap cutter, this tool for tiling with glazed tiles consists of a platform topped by a frame along which a cutter wheel slides. The tile is positioned on the padded platform, with one side flush to a fence at the head to hold the workpiece square.

The cutting wheel, quite like the wheel on a glass cutter, is mounted on a lever mechanism that allows considerable leverage to be applied. The wheel is pressed against the tile to score its glazed surface. The tile is then pressured with the cutter lever to snap the tile apart.

Tile cutters vary significantly in price. Some have hardened steel cutting wheels; others have carbide cutters (these cost several times as much but last much longer). Some have larger tables; others can be set up to make accurate miter cuts.

Best For: Cutting straight cuts on glazed tile indoors

Our Recommendation: Goplus Professional Tile Cutter – Get It at Amazon for $89.98

The Goplus Tile Cutter scores tiles up to 24 inches, comes with a durable frame and nonslip feet, and makes precision scores.

2. Wet Saw

A more expensive option is a wet saw, a portable circular saw mounted onto a unique frame that features a water-filled trough. A movable cutting table with an adjustable fence allows the tile to be presented to the cutting blade, which is kept cool by jets of water.

The wet tile saw is invaluable for working with thick and shaped tile and shaping curves from tile. It makes smooth, regular cuts, when used with both skill and care. If you have used a circular saw, similar safety rules apply.

Wet saws can usually be rented for reasonable daily or hourly fees. Some tile suppliers also have cutters they will rent or loan to their customers when buying tile. Before renting a wet saw or tile cutter, keep in mind that a cutter can be sufficient for most simple glazed tiling jobs, and is more reasonably priced.

Best For: Large tile projects and thick, rigid material, such as unglazed stone tiles

Our Recommendation: SKILSAW 7-inch Wet Tabletop Tile Saw – Get It at Home Depot for $145.49

This tabletop wet saw is portable. It cuts tiles up to 18 inches wide and adjusts for both right- and left-side cuts.

3. Nippers

Along with tile cutters and wet saws, nippers are another essential tile-cutting tool. The look like pliers, and like pliers, they’re available in many sizes and configurations. A basic pair of nippers will suffice for most jobs.

Nippers are used to cut curved or irregular tiles, or to nip away very thin strips from the edges of a tile. They work best when the area to be trimmed has been scored with a tile cutter or glass cutter; the nippers are then used to clip off small sections at a time. Some nippers have one flat jaw that is held flush to the glazed surface of the tile; the other jaw has a curved cutting edge that is designed to bite into the unglazed vitreous base, or bisque. Others types of nippers have two cutting edges—both designs work well. Another task for which nippers are useful is trimming away excess tile to achieve complex patterns that have been scribed on the tile’s surface.

Best For: Making irregular, small cuts to fit tile around pipes or to create mosaic tile installations

Our Recommendation: ABN Tile & Mosaic Nippers – Get at Amazon for $14.99

These tile nippers feature durable carbide nipping edges and come with nonslip grips for stability.

4. Notched Trowel

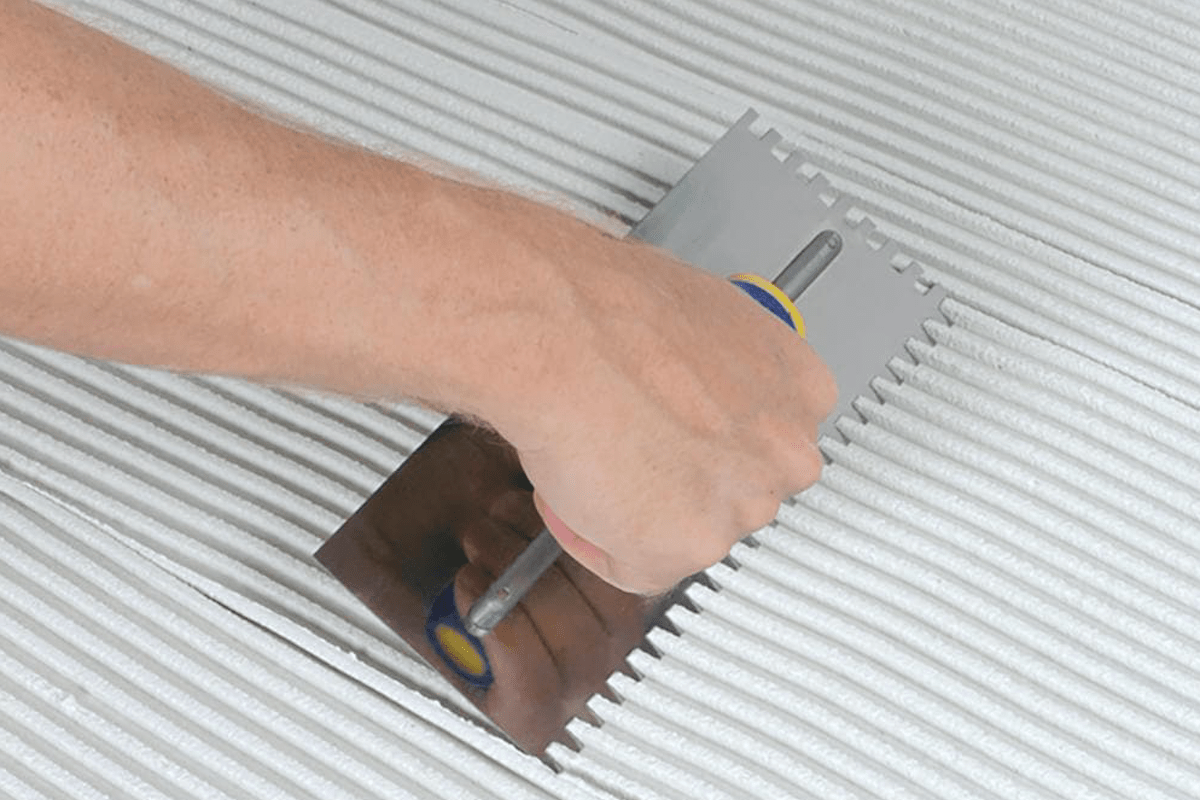

Used to spread adhesive over walls or floors before setting the tiles. a notched trowel has a flat rectangular blade and a wooden handle mounted along the center of its back. Also called a serrated-edge, adhesive, or mastic trowel, the edges of the blade are notched, sometimes in different profiles.

When you have finished laying out the job, apply the adhesive to a small wall or floor area (for example, 3-foot-square area) using the notched trowel. Smooth the adhesive or thinset evenly onto the surface, then draw the notched edge through it on a final pass, holding the trowel at a low angle. This will create a uniform series of ridgelines in which to bed the tiles.

The tiles can then be set in place, one at a time. They are pushed firmly into the adhesive, perhaps slightly twisting to bed them securely and evenly. As you finish each section, check that the areas are plumb and level.

Trowels come with various sized notches, and some notches are square while others are triangular. Don’t pick just any notched trowel—the different size notches create thinner or thicker beds of thinset or adhesive. Check the tile manufacturer’s specifications to get the proper notched trowel for the type of tiles you’re installing.

Best For: Installing many types of ceramic and porcelain tiles up to 8 inches by 8 inches

Our Recommendation: QEP 1/4-inch by 1/4-inch Comfort Grip Square-Notch Trowel – Get at The Home Depot for $13.37

This square-notch trowel is suitable for a variety of tiles, and it comes with a padded, nonslip grip for comfort.

5. Grout Float

After the tile is in place and the adhesive or thinset has set for 24 hours or longer (follow the adhesive or mortar package instructions), it’s time to grout. A sponge can be used for this purpose, but the job is a good deal easier if you have a grout float. (You’ll still need a sponge, though, to remove grout haze from the tiles after the grout is applied.)

The tile grout float looks somewhat like a trowel, with a handle at the center of its back. The float’s body may be made from wood or another rigid material. Its working surface is made of rubber and it’s also known as a rubber float.

It is used as a trowel by holding the long edge at a low angle to the tile surface while sweeping it across the area. Exerting a bit of pressure will help work the grout between the tiles. Follow with a sponge to remove the grout residue from the tile surfaces. Most grout floats can be used with either sanded or unsanded grout, but look for a float specified for use with epoxy grout if you’ll be installing that product.

Best For: Smoothing wet grout into grout joints in recently laid tiles

Our Recommendation: QEP 4 in. by 9.5 in. Universal Gum Rubber Grout Float – Get at The Home Depot for $18.57

This grout float is suitable for filling grout joints in all types of tile projects, and it comes with a nonslip handle for stability.

6. Diamond Blades

Diamond blades don’t contain real diamonds (mined from the earth) despite their name. Instead, they have rigid synthetic diamond particles embedded in the blade’s sharp cutting edge. Diamond blades are used in wet saws for making clean cuts on various types of tile.

The correct diamond blade for any tiling project must match the installed type of tile. Fortunately, getting the right one is relatively simple because the blades are labeled by the type of tile they’re designed to cut. For example, a diamond blade suitable exclusively for cutting ceramic tile may not be durable enough for porcelain tile, which is a more rigid material. Likewise, cutting stone tiles requires a specific blade. Be sure to check the label when choosing the blade.

Best For: Cutting hard tiles, including porcelain, marble, ceramic, and granite

Our Recommendation: RIDGID 7 in. Premium Tile Diamond Blade – Get at The Home Depot for $53.57

This all-purpose, professional-grade diamond blade is designed to cut through hard tile types, including granite and porcelain without chipping them.

7. Paddle Mixer

While premixed types of thinset and grout are available, both products often come in a powdered form that must be mixed thoroughly with water. Mixing by hand, although doable, is labor-intensive and tedious. Hand-mixing increases the risk of powder lumps remaining in the mixture that can reduce the product’s adhesion.

Paddle mixers—or paddle bits used as DIY alternatives, like QEP’s Paddle Bit, that fit heavy-duty drills—make quick work of mixing powered grout or thinset. A dedicated paddle mixer features a two-hand grip that makes it easy to securely grasp the power tool while mixing large batches. Paddle mixers save a lot of time for large tiling projects and ensure that adhesive and grout is uniformly mixed.

Best for: Mixing large batches of thinset or grout

Our recommendation: Kobalt Mud Mixer 1.9-HP – Get It at Lowe’s for $149

This heavy-duty paddle mixer comes with a two-hand, nonslip comfort grip. Its powerful, 1.9-HP motor is ideal for mixing large batches.

8. Tile Leveling System

Tiles add to a room’s style, but if they’re uneven—they can look amateurish, or worse—they can be a tripping hazard. Since an uneven subfloor can result in tiles that aren’t level, the first step is to ensure the floor beneath is level, which may require a floor leveling compound.

When the edge of one tile is higher than the edge of an adjacent tile, the issue is known as “lippage,” which means the higher tile has a raised lip. While lippage isn’t as noticeable on wall tiles, it can create significant problems on the floor.

Lippage on floor tiles can catch dirt during sweeping or mopping, and it can feel uneven underfoot. If it’s bad enough, it can result in tripping. Tiling leveling tools can help achieve a flat floor free from lippage.

Professional tile setters may use straight edges to ensure all tiles are of a uniform height during installation, but DIYers may want additional assurance. A tile leveling system offers installers a way of carefully aligning tiles at a consistent height. This can be accomplished by using special spacers between the tiles and then slipping braces within openings in the spacers. The braces put equal pressure on the tiles on both sides to keep them at the same level. When the thinset cures, the spacers and braces are removed before grouting.

Best For: Ensuring a level floor with minimal lippage

Our Recommendation: T-Lock PERFECT LEVEL MASTER Professional Tile Leveling System – Get It at Amazon for $70.94

This tile leveling system helps ensure each tile is the same height as its neighboring tiles to create a smooth, flat surface. (T-Lock braces are sold separately.)

Final Thoughts

Installing tile was once a project left almost entirely to professional tile setters, but with today’s tiling tools and accessories, it’s become a DIY project for handy homeowners. With the right materials needed for tiling and special tools for scoring, snapping, or cutting, nearly anyone can make accurate cuts. Power mixers or paddle bits help blend grout and adhesives with ease, so laying tile is quicker and simpler.

FAQs About Tiling Tools

If you’re still unsure which implements you need to complete your tiling job or how to use the tools we’ve described above, the following frequently asked questions may help you.

Q. What is a grouting tool?

A grouting tool or float is a rubber-padded trowel used to smooth wet grout into the joints between tiles.

Q. What do I need to tile a hearth?

In addition to measuring tape and a pencil, you’ll need the tiles, a tile cutter or wet saw, adhesive (thinset), a notched trowel, and a paddle bit or mixer (if you’re not using premixed grout). You may also want to use tile spacers, which double as a tile measuring tool to keep tiles evenly spaced. You’ll need grout, a grout float, and a sponge to clean away excess grout from the tile surfaces for the grouting process.

Q. What are the four most essential tools used in tile installation?

The four most essential tile tools are: a tile cutter or wet saw, a notched trowel, tile spacers, and a grout float. And while they’re not essential for installing tile, if you’re working on floor tile, it pays to invest in a good pair of knee pads.