We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Whether gluing materials, building picture frames, assembling cabinetry, or doing other shop activities, having the right clamp for each job can be critical. A good set of woodworking clamps is an excellent addition to any hand tool collection, whether you plan to use them frequently or occasionally.

Woodworkers use clamps for any number of jobs around the shop when an extra pair of hands is needed. Depending on your use, the best woodworking clamp for your project may be one of several varieties. Our top pick, the WEN 10236F2 Quick-Adjust 36-Inch Steel Bar Clamps, have a handy quick-adjust feature and can handle just about any woodworking job, whether small or large.

Keep reading to learn about some of the best woodworking clamps that you can choose for your workshop.

- BEST OVERALL: WEN 10236F2 Quick-Adjust 36-Inch Steel Bar Clamps

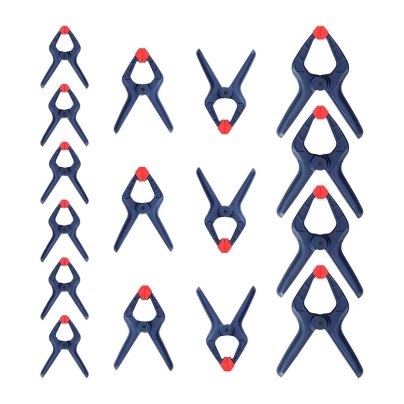

↓ Jump to Review - BEST BANG FOR THE BUCK: WORKPRO 16-Piece Nylon Spring Clamp Set

↓ Jump to Review - BEST SET: Bessey KLI-S Kliklamp Systainer Set with 16 Clamps

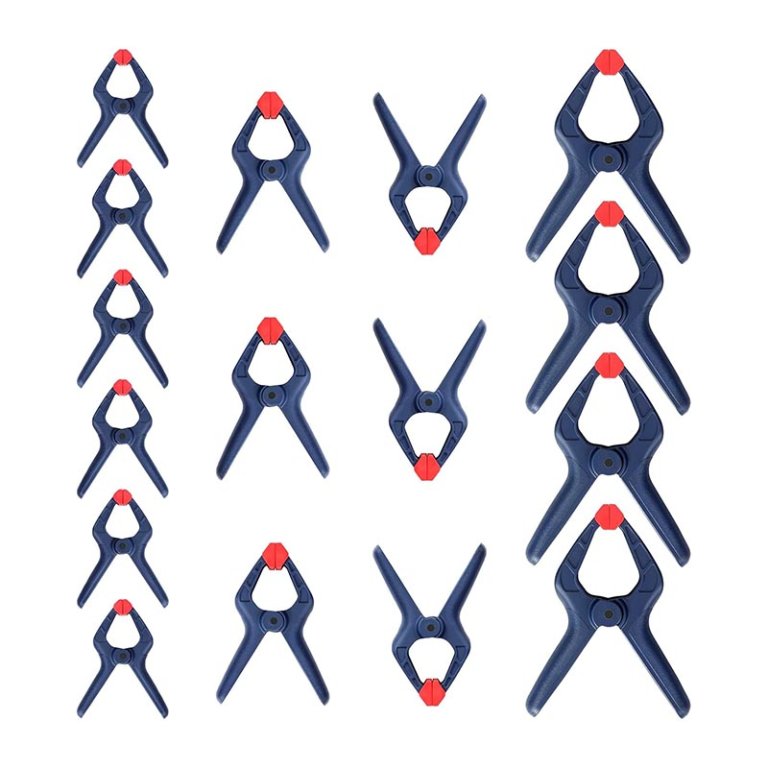

↓ Jump to Review - BEST SPRING CLAMP: WORKPRO 20-Piece Steel Spring Clamp Set

↓ Jump to Review - BEST CORNER CLAMP: Housolution Single Handle Right Angle Clamp

↓ Jump to Review - BEST PIPE CLAMP: Bessey BPC-H34 ¾-Inch H Style Pipe Clamp

↓ Jump to Review - BEST F-CLAMP: Yost Tools F124 24” F-Clamp

↓ Jump to Review - BEST C-CLAMP: Irwin QUICK-GRIP C Clamp

↓ Jump to Review - BEST EDGE CLAMP: Bessey KT5-1CP single spindle edge clamp

↓ Jump to Review - BEST STRAIGHT EDGE: ProGrip Straight Edge Clamps

↓ Jump to Review

Our Top Picks

Picking the right woodworking clamp is not as simple as it seems. Intended use, clamping power, durability, and construction quality are vital considerations when shopping for suitable clamps for your workshop. The following is a list of some of the best woodworking clamps based on type.er, durability, and construction quality are vital considerations when shopping for suitable clamps for your workshop. The following is a list of some of the best woodworking clamps based on type.

Best Overall

WEN 10236F2 Quick-Adjust 36-Inch Steel Bar Clamps

See ItThis versatile pair of clamps from WEN is perfect for dozens of household and woodworking jobs. Non-marring clamp heads ensure your material isn’t scuffed or damaged while providing up to 600 psi of clamping capability.

The steel rail is 36 inches long, and the throat is 2.5 inches, making the WEN clamps large enough to accommodate just about any woodworking job in your shop. The quick-adjust feature allows you to adjust clamp length without pressing any buttons.

Made of steel, these clamps are capable of holding up to their own pressure. The rod offers micro-adjustments as small as .05 inches, thanks to the ridged shaft. And carpenters can adjust it even further with the micro-adjustment knob.

Best Bang for the Buck

WORKPRO 16-Piece Nylon Spring Clamp Set

See ItThe package includes 16 clamps ranging in jaw size from 1⅜ inch to 2¼ inches. Nylon construction means oiling metal parts is not required, but keep in mind these clamps may not be as long-lasting as those of steel construction. Durable pads protect the finish of your project while making sure materials don’t slide or move when you don’t want them to.

The spring mechanism creates long-lasting pressure, and the ergonomic grips are comfortable on the hands. Overall, the WORKPRO set provides a friendly price point for a set of clamps that will cover a great deal of a woodworker’s needs.

Best Set

Bessey KLI-S Kliklamp Systainer Set with 16 Clamps

See ItThe Bessey KLI-S Systainer Set comes with 16 bar clamps packaged in a T-Loc carrying case for easy transportation, storage, and protection.

The sliding arms are made of magnesium, making the clamps lightweight without sacrificing clamping power. The multi-state ratchet system is easy to use and capable of exerting high levels of pressure through just a few fingers. The clamping arm can accommodate curved, angular, and pointed materials and is constructed of fiberglass reinforced polyamide for high durability.

The clamps in the Bessey set range from 4½ to 10 inches, making the Bessey set a lightweight, strong, transportable clamp set for most woodworking applications.

Best Spring Clamp

WORKPRO 20-Piece Steel Spring Clamp Set

See ItThis 20-piece steel spring clamp set from WORKPRO can handle light clamping. The PVC-coated tips and handles help prevent slippage, while steel construction provides durability and reliability.

The set comes in several jaw sizes ranging from ¾ inch to 1 inch, and tempered steel springs ensure the clamp applies steady pressure. This spring set is excellent for jobs that don’t call for significant gaps, but it may not be ideal for edge gluing or heavier-duty applications.

A zinc coating helps prevent corrosion and rusting, making these spring clamps durable, but regular oiling and proper storage will go a long way in getting the most out of the clamps.

Best Corner Clamp

Housolution Single Handle Right Angle Clamp

See ItThe Housolution corner clamp is exclusively made for creating perfect right angle joints. Constructed from durable premium aluminum alloy, the Housolution can accommodate material thicknesses up to 2.68 inches through a swing-jaw design that allows for single-handed jaw adjustments.

This clamp is primarily for those who need to create right angles and will not function for clamping needs outside of this category. For the carpenter who designs frames, cabinetry, butt joints, or other right-angled materials, the Housolution is an excellent choice. However, it will not be the only clamp you’ll ever need, as it is not designed to perform outside of these tasks.

Best Pipe Clamp

Bessey BPC-H34 ¾-Inch H-Style Pipe Clamp

See ItWith its H-shaped assembly, the Bessey BPC-H34 Pipe Clamp provides a stable platform on which to rest your project. The legs also provide extra height, making it easy to clear the material when turning the handle. Soft jaw caps come with this pipe clamp to help prevent surface marring.

The BPC-H34 boasts a solid construction. The clutch plates are coated with zinc to prevent wear, the spindle is covered with black oxide to help ensure smooth operation, and the finish is powder coated to fight against corrosion. Most pipe clamps do not include the pipe itself. The BPC-H34 will work on a pipe of any length so long as it is ¾ inch wide.

Best F-Clamp

Yost Tools F124 24” F-Clamp

See ItThe medium-duty Yost F124 strikes a nice balance between power and delicacy. Swiveling jaw pads with plastic coverings help protect the material finish. The powder-coated finish combats corrosion and wear, and the comfort-grip handles are easier on the hands than similar clamps made from wood. The twist grip allows you to apply serious torque when a lot of pressure is required.

The throat depth is 2½ inches, enough for most jobs, and the clamp head employs a 5-plate clutch system that slides smoothly on a 24-inch serrated steel rail. The Yost is long enough for most work encountered in a woodshop, though some jobs may require a larger clamp.

Best C-Clamp

Irwin QUICK-GRIP C Clamp

See ItC-clamps are the most common type of clamp for two reasons: They work in nearly every situation, and their simple design makes use and maintenance easy. The Irwin Quick-Grip lives up to this reputation.

Swivel pads accommodate strange angles, a large handle makes for more significant pressure with less effort, and durable steel construction scores points in the durability department. This 6-inch clamp has a 3½-inch throat, and Irwin boasts a clamping power of up to 1,000 pounds, which is more than enough for nearly every application.

The Irwin Quick-Grip C-Clamp is the quintessential clamp: strong and versatile. However, it is limited in adjustment by its C-shaped design.

Best Edge Clamp

Bessey KT5-1CP single spindle edge clamp

See ItThe KT5-1CP is interesting because it is not a clamp, but it turns your already-owned clamps into an edge clamp. For use with bar clamps, the single spindle design fastens to any bar clamp under a ½ inch thick, offering three dimensions of clamping without needing a specialized edge clamp.

Bessey’s patented nonslip locking system keeps materials secure from three sides. It is easy to use and highly durable, but it requires ownership of other types of clamps to function.

Best Straight Edge

ProGrip Straight Edge Clamps

See ItThe ProGrip Straight Edge Clamps are the best straight-edge clamps on the market. They come in 24-, 35-, and 50-inch lengths and have an easy-to-use design that even a novice will have no trouble using. While other clamps have one locking position, the ProGrip clamps have three, so you can choose the right amount of pressure for your project.

These clamps also have a wide profile at 2.1875 inches, which helps keep plywood boards rigid while you work. You’ll notice both standard and metric markings on the guides, making it easy to measure.

Jump to Our Top Picks

What to Consider When Choosing Woodworking Clamps

The first thing to consider when shopping for clamps is how they will be used. Not all clamps do the same thing. Some specialized clamps are only suitable for a specific job, while others are versatile in their application. When searching for the best woodworking clamps for your use, consider the following.

Types of Clamps

Clamps are available in a wide variety of sizes and styles. While all of them apply pressure to hold materials in place, they don’t create pressure in the same way. Many rely on springs to generate this pressure, others use hand-turned threaded rods, and some are used in other specific ways. Read on to discover which characteristics might make a woodworking clamp best suited for your projects.

Spring Clamp

Spring clamps, sometimes referred to as pinch or hand clamps, are simple but strong. They derive their power from a spring that holds the jaws tightly closed. Spring clamps are often used for jobs too delicate for heavier-duty clamps.

The jaws of some spring clamps close symmetrically, while others pinch in a triangle shape that is better for thinner materials. Spring clamps remain firmly closed until opened by the user. They tend to be small, portable, and convenient for dozens of household chores and projects.

Corner Clamp

Corner clamps apply pressure through threaded, steel sliding pins. The woodworker turns the handle, which tightens down the clamp, holding the project in place. Corner clamps can be operated by hand or fastened to a workbench for extra stability.

Corner clamps are used primarily in projects requiring right angles, such as building picture frames. They’re also handy for fastening miter joints (two pieces with 45-degree ends held together to create a right angle), T-joints (two materials attached in a T-shape), and butt joints (two materials attached at a right angle by the butt ends).

Pipe Clamp

Pipe clamps are strong, inexpensive clamps used for edge gluing, assembling cabinets, fixing leaks, holding pipes in place, and other functions. They are sold as a pair of adjustable clamp heads.

The user slides a pipe through a hole in the stationary clamp, then inserts the pipe into the moving clamp head, which employs a clutch system for adjustment of length. One of the conveniences of pipe clamps is their ability to be as long as the woodworker needs. If you need to clamp larger material, you can just use a bigger pipe.

F-Clamp

Similar to a pipe clamp, F-clamps (a type of bar clamp) employ adjustable sliding clamp heads. Unlike pipe clamps, bar clamps are complete units that can accommodate projects ranging from 4 to 48 inches.

F-clamps lack some of the adjustability of pipe clamps as they are limited by the size of the perpendicular bar. Bar clamps may come with quick-release clamp heads that make adjustments simple. Additionally, some have holes drilled in them where pins can be inserted for added security. F-clamps are typically used for heavy-duty jobs that require a wide span between clamp heads.

C-Clamp

C-clamps are the most common type of woodworking clamp. Formerly known as carriage clamps, C-clamps are made of forged steel or cast iron in the shape of a C into which a threaded steel rod is inserted. The user turns the handle to close the span and hold materials in place.

C-clamps are common because they are portable, strong, and simple, and they are valuable for myriad household and woodworking functions. C-clamps come in a variety of sizes ranging from ¾ inch to 14 inches. While not as adjustable as a pipe or bar clamp, a good set of C-clamps will cover the majority of woodshop requirements.

Edge Clamp

Edge clamps are perhaps the most specialized clamp on this list.

As their name implies, edge clamps fasten to the edge of a material. These clamps are most useful for holding materials in place when one material is exceptionally wide, such as when gluing trim to plywood. They have three screws, allowing the woodworker to adjust on multiple axes.

Clamping Power

When using clamps, sometimes less is more. Exerting too much pressure on a woodworking project may result in poor joints, bad glue jobs, and even damage to the clamp. One wood glue manufacturer recommends a force of 100 to 150 pounds per square inch (psi) when gluing softwoods. This number increases to 175 to 250 psi for hardwoods.

F-clamps, pipe clamps, and C-clamps can exert pressure in the range of 400 to 2000 psi, while spring clamps tend to be capable of significantly less.

Size

Clamps vary when it comes to how much material they can accommodate. Clamp size is measured by jaw capacity, which is the dimension of the largest span the clamp can open. Throat size indicates the clamp’s depth. Someone who is edge gluing a table will need a much larger clamp, such as an F-clamp, than someone who is building a birdhouse.

The unit may range in size from less than an inch to several feet, with corresponding changes in weight to match. Brainstorm the most common uses of your woodworking clamps to determine which size clamp will find the most use in your shop.

Maneuverability

Some C-clamps can fit into a pocket, while F-clamps or pipe clamps may be several feet long and weigh dozens of pounds. Being able to easily move clamps around the shop, take to the job site, or store in your toolbox or tool belt when working on a job site can be an important consideration.

Because clamps vary widely in purpose and function, after you’ve figured out which clamp is best for your use, be sure to consider how often you will need to move them. Aside from portability and maneuverability, some clamps require two-handed operation, while others can be operated with one hand. As with any carpenter’s tool, being able to transport and utilize clamps is essential.

Protection

Clamps are made from a variety of materials ranging from plastic to steel. As with any tool, choosing clamps made from high-quality materials and properly maintaining them is the key to a long, productive life.

Maximizing the life of your clamp means regular, basic maintenance. Keeping your clamp clean and dry will go a long way in getting the most use. Wipe your clamp clean of moisture, glue, and other debris after each use. For clamps with metal parts, regular oiling is a must. If your clamps have wooden parts, wipe them down with linseed oil to prevent moisture penetration. When not in use, make sure clamps are stored in a safe, dry place such as a workbench or toolbox.

FAQs

If you still have some lingering questions about woodworking clamps, the following common questions and answers may help.

Woodworking clamps apply steady pressure through a variety of mechanisms, including springs, threaded steel rods, and locking mechanisms to secure woodworking materials.

Glue drying time varies based on the type of glue and air temperature, but a good rule of thumb is to wait 24 hours to be sure the bond is completely set before applying stress to the joint.

With proper maintenance, quality woodworking clamps can last beyond the lifetime of the user.