We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

One of the key accessories for a table saw is a sturdy fence. It is almost impossible to cut boards and sheet material accurately without one.

All table saws come with a fence included, but some lack the precision necessary for quality woodworking. Alternatively, if a table fence has been damaged, it presents the opportunity to upgrade rather than simply finding a like-for-like replacement.

The following article looks at the important features that need to be considered and showcases our choices for the best table saw fences on the market right now.

- BEST OVERALL: Delta T3 30-Inch Fence System

- BEST BANG FOR THE BUCK: Shop Fox W1410 Fence With Standard Rails

- BEST PRECISION: Vega U26 Table Saw Fence System

- MOST VERSATILE: Shop Fox W1716 Aluma-Classic Fence

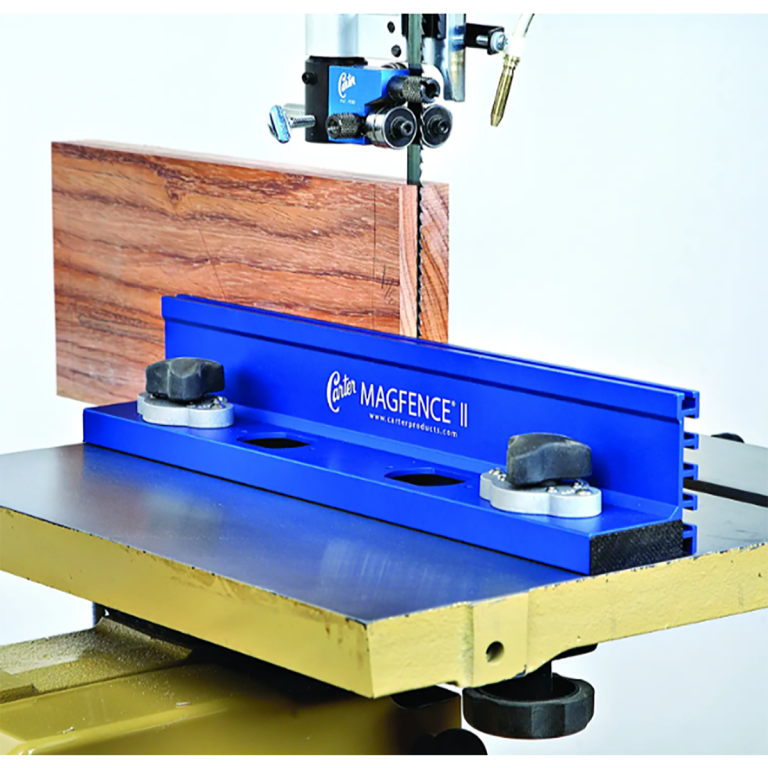

- BEST MAGNETIC: Carter Magfence II Band Saw Fence

How We Chose the Best Table Saw Fences

The author has owned his own woodshop for 10 years and has experience with several table saw fences. The Bob Vila team also checked leading manufacturers for the latest developments and innovations. In fact, little has changed, though digital readouts can now be added.

As stated above, there are few reasons to change an existing table saw fence unless the original is in poor condition or gets damaged. Also keep in mind that there are relatively few aftermarket options. Though the choices are limited, we still wanted to offer as wide a range of table saw fences as possible, and our picks reflect this.

Our Top Picks

It’s now time to look at some real-world examples of table saw fences. The following are what we consider to be the best table saw fences currently available and will fit a wide variety of saws.

Best Overall

Delta T3 30-Inch Fence System

See ItPros

- Rigid T-square construction is easy to use; suitable for pros and first timers

- 3-point locking system with hairline pointers for accuracy while in use

- Adjustable for added accuracy depending on the cutting task

Cons

- No microadjusters integrated into the design; may not be ideal for some users

- Rails may need to be drilled

Product Specs

- Fence length: 37 inches

- Fence height: 2½ inches

- Maximum rip: 13½ inches on the left; 30 inches on the right

Delta table saws and accessories are widely regarded for their high-quality construction and durability. The Delta T3 table saw fence features a T-square design made from rigid tubular steel. It has a three-point locking system with hairline pointers on either side to check that it is parallel with the blade. Delta claims an accuracy of within 1/64 of an inch. Adjusting screws are provided to ensure the table fence is also set at 90 degrees to the table.

Although the fence length is given as 37 inches, only 30 inches of this runs over the table. Nevertheless, that is more than enough for most saws. Rails are predrilled to fit Delta saws, but additional holes may be required to fit other models. Fortunately, this is not a difficult task, and fitting is relatively straightforward. The fence clamps to the front rail, so strictly speaking, the rear rail isn’t necessary, but it does provide an additional support point, rather than the fence rubbing across the surface of the table.

Get the Delta table saw fence system at Amazon, The Home Depot, or Acme Tools.

Best Bang for the Buck

Shop Fox W1410 Fence With Standard Rails

See ItPros

- Runs on ball-bearing guides for smooth movement while in use

- Fine-positioning knobs and special track for right- or left-handed use

- Very competitive price compared to other table saw fences available

Cons

- Fits only 27-inch tables; may not be suitable for some users

- Time-consuming installation compared to most table saws’ fences

Product Specs

- Fence length: 30 inches

- Fence height: 3½ inches

- Maximum rip: 7½ inches on the left; 25 inches on the right

The Shop Fox W1410 is a T-square design, but it is unusual in that it clamps to both the front and rear of the table. Although this means there’s virtually no chance of the saw fence deflecting under pressure, which can happen with some cheap table saw fences, it also means that table size is critical. It has to be 27 inches deep, plus or minus ¼ of an inch. This is a fairly common size for table saws but is by no means universal.

Ball-bearing guides mean that the aluminum-and-steel construction glides particularly smoothly. There are microadjusters (Shop Fox calls them fine-positioning knobs) on both sides of the fence clamp, allowing for right- or left-handed use.

As is often the case, rails may need to be drilled to suit the table saw. Shop Fox instructions recommend drilling the table itself, and they provide a drill and tap to do this, though these parts are not of high quality. The instruction manual outlines several steps for adjusting front and rear clamps, and although this ensures smooth operation of the table fence, it is a time-consuming process.

Get the Shop Fox W1410 table saw fence at Amazon or The Home Depot.

Best Precision

Vega U26 Table Saw Fence System

See ItPros

- High-quality components throughout; made with T6 high-strength aluminum

- Rapid installation compared to some of the options on this list

- Locking mechanism integrated into the design for added accuracy while in use

Cons

- Mounting brackets may be poorly finished

Product Specs

- Fence length: 36 inches

- Fence height: Unspecified

- Maximum rip: 8 inches to the left; 26 inches to the right

The Vega U26 has a sturdy box-section aluminum fence that follows the popular T-square pattern. Similar to most table saws of this type, it uses simple but effective cam locking. The headline feature is in the fence head, which is the part that supports this locking mechanism.

It’s made of high-strength extruded aluminum that slides easily along the chrome-plated steel rail. Once close to the desired position, the microadjuster can be used. The thumbwheel moves the fence just 1/16 of an inch for a full rotation, so precision of just a few thousandths of an inch is possible.

Fitting the Vega U26 table saw fence system is easy, and the manufacturer claims can be done in as little as 15 minutes. Mounting holes are provided to suit most saws, but even if additional holes are required, the brackets are made of aluminum, so they are easier to drill than steel. Models with rip capacities of 40 inches and 50 inches are available for those with larger saws.

Get the Vega table saw fence system at Amazon, Tools Plus, or Rockler.

Most Versatile

Shop Fox W1716 Aluma-Classic Fence

See ItPros

- Durable steel-and-aluminum construction lasts for years of use

- Wide “T” section provides good support while in use

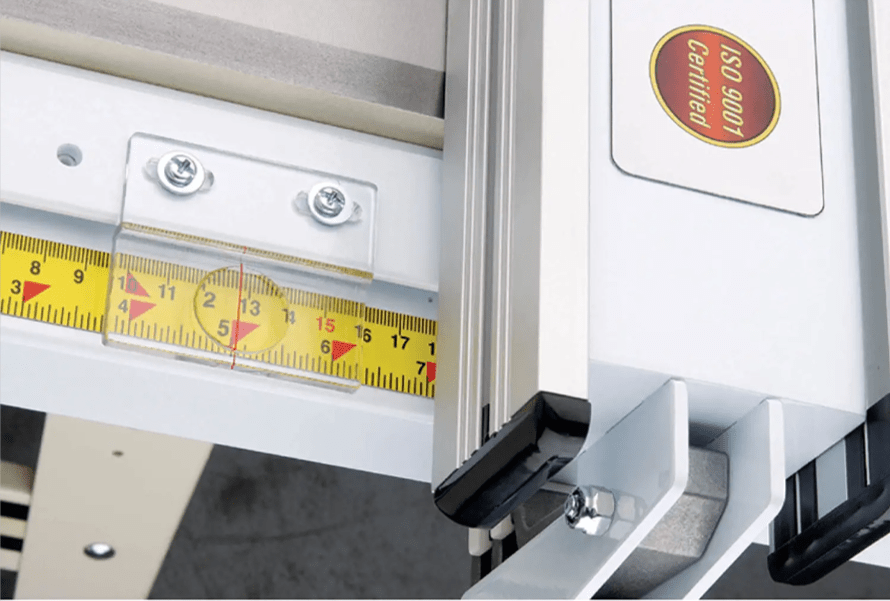

- Magnified cursor lens for quick positioning

Cons

- Included instructions could be clearer

- No microadjusters integrated into the design

Product Specs

- Fence length: 57 inches

- Fence height: Unspecified

- Maximum rip: 30 inches to the right

The need to fit a rear rail can restrict the versatility of some table saw fences. However, not having that support can mean that the fence deflects when under pressure, so cutting isn’t accurate. The Shop Fox W1716 table saw fence is designed to overcome both problems and can be fitted with or without the rear rail. The steel “T” section that runs along the front rail is longer than many, thus providing the necessary strength and support to keep the fence parallel with the blade.

A magnified cursor helps with positioning the saw fence, and the heavy-duty cam lock ensures it stays in place. However, there are no microadjusters, which is disappointing on a fence at this price.

Despite the use of aluminum for the fence itself, this is still the heaviest table saw fence we looked at, so an extra pair of hands when fitting will be welcomed. The manual can be a little confusing, so help in understanding the instructions might also be appreciated.

Get the Shop Fox W1716 table saw fence at Amazon or The Home Depot.

Best Magnetic

Carter Magfence II Band Saw Fence

See ItPros

- Magnetic fence system integrated for exceptional ease of use and convenience

- Can be used on any steel or cast-iron table

- Tremendous versatility; can be used on band saws, pillar drills, drum sanders, and spindle sanders

Cons

- Light-duty sawing only; may not be as durable as most table saws’ fences

- Not suitable for use with aluminum tables

Product Specs

- Fence length: 15 inches

- Fence height: 3 inches

- Maximum rip: Not applicable

The Carter Magfence II is quite different from the other table saw fences in our review. It doesn’t fit permanently; instead, it has powerful magnets that will hold it to the table saw’s surface. It isn’t really an alternative to T-square fences, but it’s a useful addition. For example, if the table saw was set up to rip a whole batch of large boards, but a smaller piece required cutting, the Carter Magfence II could be positioned quickly without moving the main fence. Once the small job was done, the magnetic fence could be removed and production continued.

The Carter Magfence II saw fence could also be used on band saws, pillar drills, drum sanders, and spindle sanders. In fact, it could be used on any workshop tool with a steel or cast-iron table. Of course, being magnetic, it will not work with saws that have aluminum tables, such as those that beginners often buy. It is also not a fence for ripping large boards or sheets because the length provides insufficient workpiece support.

Get the Carter table saw fence at Amazon or Rockler.

DIY Table Saw Fence

A basic table saw fence doesn’t need to be anything more than a length of wood or aluminum section that is known to be straight when clamped to the saw table. The disadvantage with working this way is that the fence has to be reset carefully and remeasured every time the user makes a different cut.

Creating a sliding table saw fence to suit the user’s existing table rails isn’t as difficult as many people fear. Half-inch plywood has the necessary rigidity, but laminated board or metal may also be used. With just a couple of pieces of hardware, it is also possible to make an effective elliptical lever clamp. Numerous plans and instructional videos are available online to guide the DIYer.

The cost of materials will be significantly lower than the cost of a commercial alternative, but accuracy in construction is absolutely vital. It will take skill and care to build a table saw fence that is as precise as the ones we feature in our top picks.

Jump to Our Top Picks

What to Consider When Choosing a Table Saw Fence

If a table saw isn’t delivering consistent accuracy, the fence may well be at fault. It may not be particularly well-made. If it doesn’t clamp securely or isn’t rigid, then it could deflect during the cut. To assess the quality of a table saw fence and its suitability for a particular saw, the following features should be considered.

Type

There are two types of table saw fence: standard (sometimes called sliding) and T-square. Sliding table saw fences are often those supplied with smaller, portable table saws. They run along rails fitted to the front and back of the saw table. On higher quality models, a rack-and-pinion drive allows for more precise positioning.

T-square table saw fences also run along a rail on the front of the table, usually with a three-point locking system. This provides strong support and holds the main part of the table saw fence in place. As a result, this type doesn’t always need a rail on the far side of the table, though a rail is often supplied as an option. If the T-square fence requires fitting only on the front of the table, it doesn’t need to be a precise length. The fence can be shorter or longer than the table width and still function perfectly well.

Almost all aftermarket table saw fences—that is, those not made by a particular table saw manufacturer—are the T-square type.

Compatibility

Standard table saw fences need to be a specific length and cannot be modified, so their versatility is limited. Standard table saw fences are often brand specific, so a DeWalt fence, for example, will fit only DeWalt saws.

T-square table saw fences generally fit a wider range of saws. However, the mounting holes for their rails are not universal, so compatibility still needs to be checked.

Typically, the rails on a table saw fence can be modified by drilling additional holes so it then suits the layout of a particular saw. This is fairly common practice, and several instructional videos are available for woodworkers who would rather make modifications than choose a different fence.

Rip Capacity

Rip capacity (or ripping capacity) is the maximum cut that can be made. In other words, it’s the distance between the blade and the table saw fence. Rip capacity is normally measured to both the left and right of the blade, and usually guide rails allow the fence to be mounted on either side. However, the right-hand side of the blade always has greater rip capacity, and that may be the only figure given.

Generally speaking, the rails should allow the fence to slide down to the far-right extremity of the saw table, therefore maximizing the rip capacity. Rail extensions often can be purchased if those supplied are not long enough.

In some cases the opposite is true, and the rails extend beyond the table. Additional table and leg sections are available for many saws. However, rails that are too long can be awkward if shop space is limited.

Material

The main body of the table saw fence is made from either aluminum or steel, or a combination of both. Strictly speaking, steel is stronger while aluminum is lighter, though both provide equally good rigidity in the way they are formed for table saw use.

Some high-quality fences have laminated plywood faces. This material is intended to make the wood being sawed slide more easily across the surface. The downside is that the laminate eventually will wear and need to be replaced, and although it’s not difficult, it is time-consuming.

The mounting rails are almost always made of steel. They need to be strong to resist the clamping forces and the wear of the fence attachment running up and down them regularly.

Additional Features

Though table saw fence systems usually have a clear measuring scale, and some even have a small magnifying glass to make reading the scale very easy, positioning the table saw fence accurately can be a bit hit-and-miss. Microadjusters allow very precise placement by using thumbwheels to move the fence the last few fractions of an inch. Unfortunately, they are not always fitted, though several are available separately.

Digital readouts are another option, providing the user with a quick and precise visual display rather than the user having to check ruler markings. However, once again, these are usually an aftermarket extra rather than a feature that is included with the fence.

Tips for Using and Maintaining Table Saw Fences

The best table saw fences should be fairly easy to set up and use, but it is important to follow the manufacturer’s instructions to ensure maximum accuracy.

- Make sure to keep the table saw and fence as clean as possible. Any sawdust, wood chips, or dirt caught between contact areas can impact precision. A shop vac or dust-extractor hose can be used to reach difficult areas. Take the fence off from time to time for a thorough clean.

- There’s an old woodworker’s adage that says one should measure twice and cut once. That applies to table saw fences, too. Check settings carefully.

- A feather board can be clamped to the table to ensure the user’s work stays in contact with the fence.

- Always use a push stick when feeding stock to keep hands away from the saw blade.

FAQs

We have discussed the key features of table saw fences and looked at some real-world examples. In the following section, we consider questions of a general nature that crop up frequently. The comprehensive answers should clarify how the best table saw fences can benefit your woodworking.

Yes. A miter gauge could be used to guide the workpiece through the blade and is fine for crosscutting planks and small section stock. It’s also possible (though seldom recommended) to work freehand. However, control is difficult, particularly with large sheet material, and inaccuracies are likely to creep in. A fence is a necessity for quality woodworking.

Some are, but others may require drilling of the table saw or removal of some components. It is a good idea to check compatibility, or what work may be required, before you buy.

Cheap table saws often come with poor fences, making it difficult to saw accurately. Each of the Delta, Shop Fox, and Vega table saw fences described above should allow you to work with greater precision. Another alternative is to make your own fence, as we’ve discussed above.

In theory, the fence needs only to guide the material past the saw blade. However, in our opinion, a full-width fence offers better control. The standard fences fitted to high-quality table saws are usually full width. In terms of rail length (and thus ripping capacity), it will depend on the space you have available and the sizes of material you need to cut.