We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

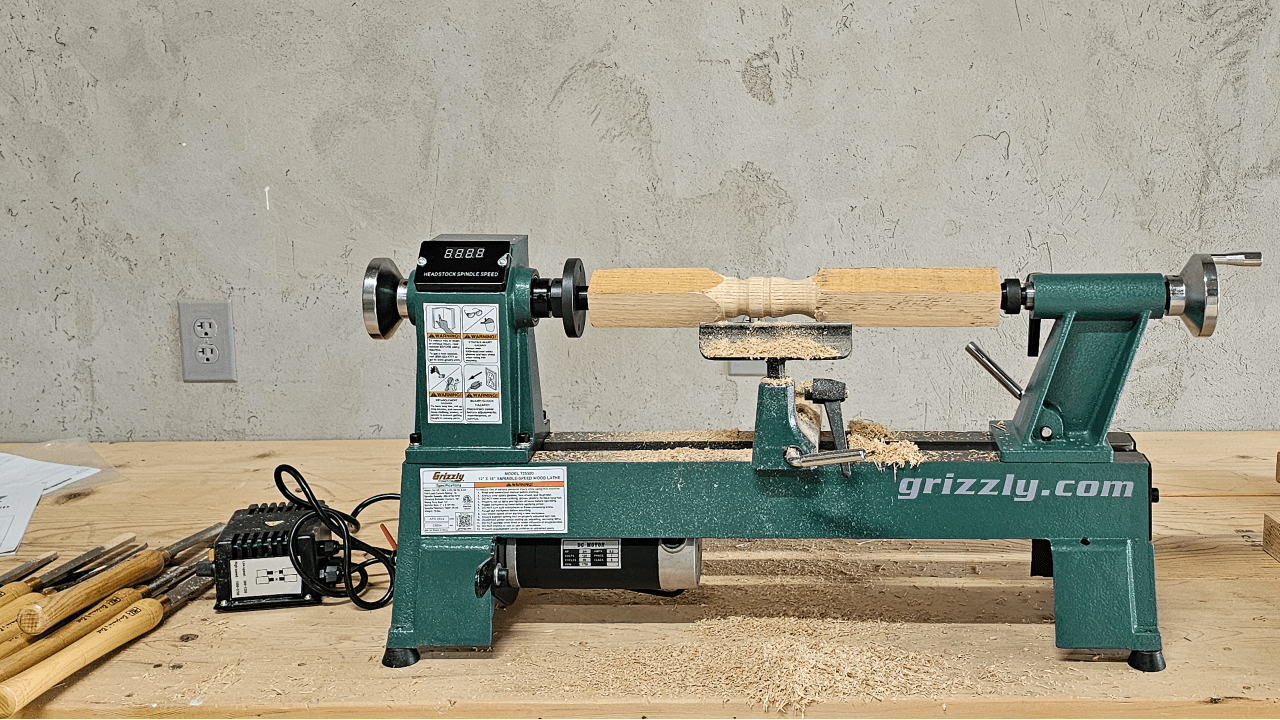

Considered a specialty power tool, a wood lathe is typically found in a woodturner’s or a furniture-maker’s shop. It’s used to create cylindrical wooden items that are symmetrical around a center axis, such as balustrades. We recently researched more than 15 DIY-friendly wood lathes before ultimately selecting one standout option—Grizzly Industrial’s 12-by-18-inch wood lathe—for testing. Our conclusion? It offers variable speed, has a solid build quality, and is a good entry-level machine for those wanting to master woodturning skills.

If you’re new to woodturning but considering buying a lathe, keep reading to learn essential shopping tips and considerations and to find out how the Grizzly wood lathe earned the top spot in our lineup of the best wood lathes.

Best Overall

Grizzly T25920 Variable-Speed Benchtop Wood Lathe

What We Like

- Digital readout and variable speed

- Sturdy build (79 pounds) for reduced movement during use

- Adjustable tool rest

- Relatively quiet operation

What We Don’t Like

- Wood length is limited to 18 inches

Product Specs

- Power: Corded electric

- Dimensions: 17 inches high by 38¾ inches wide by 12 inches deep

- Spindle Speed: Variable: 300 to 3,700 RPM

- Material: Cast iron

- Swing over bed: 12 inches

- Distance between centers: 18 inches

Our Ratings: Ease of Use 4.5/5; Operation 4.8/5; Build Quality 5/5; Value 4.5/5

The first thing we noticed upon unboxing the Grizzly wood lathe was its heft! This is a well-built machine that weighs in at 79 pounds. Still, even at that weight, bolting it to a workbench is recommended to keep it from moving during operation.

Some assembly is necessary, but Grizzly’s instructions were easy to follow. We had to attach the handles and install the drive spur and the live center (the sharp parts that grip the ends of the wood and hold it in place). In all, it took about 20 minutes to get it set up.

Softer woods, such as pine and cedar, are less dense and prone to tearing or splintering when turned on a lathe, so we rounded up several pieces of hardwood stock (oak and maple) to test on the Grizzly, as hardwoods cut more cleanly and produce better results. For our turning tests, we used an 8-piece set of wood-turning tools made by PSI Woodworking on the lathe.

The Grizzly has a 12-inch swing, which means that from the center tip of the spur that holds the wood in place to the machine’s table, it’s exactly 6 inches. That will allow the user to turn a piece of wood up to 12 inches in diameter at its widest point. All the stock we tested was 2 or 3 inches in diameter. The longest wood this lathe will accept is 18 inches, which is plenty for many wood crafts. Wood lathes that accommodate much longer pieces of wood are available, but the price increases exponentially, so for beginners or hobbyists who don’t need that length the Grizzly is just right.

For the turning part of the tests, we centered our wood between the headstock and the tailstock, adjusted the tool rest so it was very close to the wood but not bumping, and then turned on the machine. We really liked the digital readout and variable speed on the lathe. We tried out several of the wood lathe tools to shape and fine-tune contours on the wood. It took some experimenting to get just the right turning speed for the wood and tools we were using, but the Grizzly ran smoothly and quietly and did fine work once adjusted correctly.

We used a full-face shield during the testing process because wood lathes do more than just create dust—they also toss out shards of wood. After a few hours turning several pieces of stock, we were ultimately impressed by the Grizzly’s performance.

What our tester says: “This wood lathe takes some getting used to, but I think it’s an excellent pick for anyone who wants to hone their skills on wood projects up to 18 inches long.”—Glenda Taylor, Product Reviews writer and tester

Get the Grizzly T25920 wood lathe at Amazon or Grizzly.

More Wood Lathes Worth Your Money

If you’re looking for a wood lathe with a smaller footprint or one that will accommodate larger pieces of wood, here are some additional models we think are worth the investment.

- Wen LA3421 Variable Speed Mini Benchtop Wood Lathe, available at Amazon or Wen.

- Delta Industrial 46-460 12½”Variable-Speed Midi Lathe, available at Amazon or The Home Depot.

- Shop Fox W1704 8” x 13” Benchtop Wood Lathe, available at Amazon, The Home Depot, or Tractor Supply Co.

- Grizzly G0462 16” x 46” Wood Lathe With DRO, available at Tractor Supply Co. or Grizzly.

- Jet JWL-1840EVS 18” x 40” Wood Lathe, available at Amazon, Lowe’s, or The Home Depot.

How Chose and Tested the Best Wood Lathes

| Testing Stats | |

| Products tested | 1 |

| Time spent testing | 3.5 hours |

| Tests performed | 4 |

| Price range | $500 |

The most challenging part of this process was choosing which wood lathe to test. After narrowing our list down to our favorite six models, we settled on the Grizzly because we’re very familiar with the quality of Grizzly Industrial machines and wanted to test a lathe that was both powerful and affordable.

We kept our hands-on tests as close as possible to actual wood-turning projects. We inserted hardwood stock (the best wood for lathe turning) in the machine, centering and securing it, and then conducted turning tests using various cutting tools to shape, gouge, contour, and fine-tune the wood. We noted the machine’s best features and what we didn’t care for. After testing, we summarized the Grizzly’s strengths and weaknesses, and we were pretty pleased with its overall performance.

What to Consider When Choosing a Wood Lathe

Before investing in a new lathe for woodturning, consider these critical product features to be sure you purchase the best wood lathe for your needs.

Types of Wood Lathes

These powerful woodworking tools come in three types: mini/benchtop, midi, and full-size.

Mini/Benchtop

A wood lathe is considered a mini or benchtop woodworking lathe if it has 20 inches or less of distance between centers (abbreviated as DBC) and 12 inches or less of swing over bed (abbreviated as SOB). Simply put, the DBC is the maximum length of wood that can be used, while the SOB refers to the maximum diameter of wood that can rotate on the lathe.

A miniature wood lathe is smaller than a midi or full-size wood lathe, making it a great option for small workspaces. It is also very good for working with small, delicate items or adding intricate details to larger items, as long as they fit within the lathe’s capacity. This type of wood lathe is usually the most affordable option, making it a great starting point for beginners.

Midi

Midi wood lathes fall between mini wood lathes and full-size wood lathes in both power and size. This type of wood lathe ranges widely in DBC, frequently dropping below 20 inches in size, but it typically remains at or above 12 inches of SOB. With the increase in size, the midi wood lathe also increases in cost, but this style is still more affordable than a full-size wood lathe.

Full Size

Full-size lathes have powerful motors and take up the most space. They typically stand on the ground at a height of about 4 feet so that you have easy access to your project. These large lathes can have a very wide DBC, ranging over 45 inches in length, and an SOB that exceeds 15 inches in diameter.

Size and Weight

When you’re looking for a new wood lathe, it’s crucial to consider the space available in your workshop or garage. Remember that these power tools are designed to be heavy so that they do not jostle the wood while you work; as such, you’ll need a sturdy surface for benchtop and midi wood lathes.

Full-size wood lathes stand about 4 feet off the ground. This means you won’t have to worry about lifting them up to a benchtop, but it also means that if you want a wood lathe this big, you need to ensure you have the floor space. Before buying a wood lathe, measure the available space and compare it to the product dimensions to ensure it will fit.

Base

The composition of a wood lathe’s base is a critical factor because it is responsible for providing a solid foundation that can absorb vibrations during operation. Even small vibrations can significantly affect the project by causing unintended cuts and gouges—not to mention being a potential safety hazard.

To help prevent this issue and keep wood steady while you work, look for a wood lathe with a cast-iron base. Cast iron is a dense, very heavy metal that ensures the wood lathe remains stable and that the vibrations caused while working do not affect the project. Even mini wood lathes will normally use cast iron to ensure that their mobile design does not compromise the project’s outcome.

Headstock and Tailstock

The headstock on a wood lathe is the side that has the power converter to the motor and will also typically include the speed control. The headstock spur is a small metal piece that extends from the headstock to the center of the wood lathe, and it is designed to pierce the wood and serve as the centerpoint, providing the necessary powered rotation.

The tailstock of the wood lathe can be adjusted to fit the length of the wood in the center of the headstock and tailstock. Once the wood is in position, the tailstock locks in place to prevent the wood from moving vertically or horizontally while still allowing it to rotate evenly. This pincer-like grip acts similar to wood clamps to hold the wood perfectly still and horizontal so the finished product will be symmetrical.

Power and Speed

The power output of a wood lathe is measured in horsepower (HP). Light-duty mini wood lathes typically have an output of about ¾ HP, while full-size wood lathes average 2 HP. The motor’s power output increases the potential speed of a wood lathe, allowing you to work at a faster speed using a full-size wood lathe than with a mini or midi wood lathe.

Speed is measured in rotations per minute (RPM) with a range of 250 to 4,000 RPMs between products. Speed is important because smaller pieces with more delicate cuts must rotate faster than large, heavy pieces to ensure that the cut is properly controlled as the cutting instrument moves through the wood.

Capacity

The capacity of a lathe machine can be determined by the DBC and the SOB.

- DBC refers to the distance between the headstock and the tailstock. This measurement determines the maximum length of wood that you can use with your wood lathe. It can range from as small as 12 inches to longer than 40 inches.

- SOB is the measurement used to determine the maximum diameter a piece of wood can have before it can no longer fit in the wood lathe. Mini wood lathes may have an SOB as small as 6 inches, while a full-size wood lathe can have a 15-inch or greater SOB, allowing you to take on much larger projects.

Tool Rest

The tool rest on a wood lathe is a feature that makes the lathe safer and more convenient. This is because the tool rest is a horizontal bar that gives you a place to position cutting tools so that they remain stable while the wood rotates against them. It’s important to ensure that you set the tool rest to the appropriate distance from the rotating wood because if it is too far away then the tool rest will not be able to provide the necessary support.

Mini and midi wood lathes typically have tool rests that fasten directly to the lathe, allowing you to get close to small projects. Full-size wood lathes can be used on larger pieces of wood, so these lathes may come with extending tool rests that fold out from the lathe to better position them for larger-scale woodworking projects.

Safety

Using a wood lathe allows you to turn all sorts of intricate projects, but the tool has fast-moving spinning parts and throws off dust and wood shavings at a high rate of speed. Safety is paramount, and operating a lathe safely requires a lot of caution. Accidents and injuries can occur from making simple mistakes, like wearing loose-fitting clothing and jewelry or leaving long hair loose that can get caught in the lathe’s rotation, pulling the operator toward the rapidly rotating wood. Remove all jewelry, wear fitted clothing, and secure hair out of the reach of the machine.

Another safety consideration is your personal protective equipment (PPE). While working with a wood lathe, you should have a full-face shield to keep your eyes, nose, and mouth safe from flying wood chips, and consider a dust mask as well if you’re sensitive to sawdust. You should also have a set of work gloves that can help keep your hands safe without interfering with your woodworking ability. Always know where the emergency stop button is when using the lathe so that in an emergency, you don’t have to look for it.

Accessories

Wood lathes require additional tools to help you get the best results. Common wood lathe accessories include chisels, gouges, spring calipers, and hones.

- Chisels are primarily used for finishing work when you use them with a wood lathe. The flat edge of a chisel can seem daunting at first because it has a higher likelihood of skipping while you are working than the double edge of the gouge. However, when used correctly, a chisel can make your project much better by smoothing the wood and reducing the need to sand to attain the same smooth surface.

- Gouges are a type of chisel that come in a range of sizes and cut profiles. Gouges are used for making broad, medium, or fine cuts. Roughing gouges, for instance, are used at the beginning to remove any surface wood you won’t need, while spindle gouges or shallow fluted gouges are intended for more precision cuts and designs.

- Spring calipers are wood lathe turning tools that are not used for cutting, sanding, or shaving wood. Instead, these simple tools are designed to measure the diameter of the wood as you work on it so that you know when you reach the desired depth of your cut. This is especially important when making several pieces that need to match, such as railing spindles or table legs.

- Hones are used to smooth the edge of the wood lathe itself and the cutting tools used with it, removing the metal burrs that develop on the edge of the metal over time. Burrs occur over time during normal use, so you won’t likely be able to avoid them. However, they are easy to remove with an inexpensive hone, giving you a clean cutting edge.

- Chucks are sloping devices that assist in holding the wood in place while turning. Wood chucks for lathes come in different sizes and shapes to suit various projects.

Tips on How to Use a Wood Lathe

- Follow the manufacturer’s safety instructions.

- Make sure the wood stock is secure on both ends before turning the machine on.

- Position the tool rest near (but not touching) the stock.

- Start at a low speed and gradually increase the speed as you get a feel for the process.

- Experiment with the cutting tools to get a feel for what each one does.

- Never touch the wood stock until it has completely stopped spinning.

- If necessary, use a small detail sander to smooth the grain in tight spots.

FAQs

Before investing in a new wood lathe, take a look at these frequently asked questions and their answers below.

You can make a wide assortment of wooden objects, including spoons, bottle stoppers, rings, pens, bowls, cups, and decorative art.

This is largely a matter of preference. Durable and abrasion-resistant, beechwood is a popular choice, especially for making bowls and other related items. It lacks a distinctive grain pattern and has a very light color. Some woodworkers may think that it is a disadvantage, but others appreciate its plainness.

Wood lathes with ⅓ to ¾ hp are ideal for turning pens and other small objects. 1 to 2 hp is well-suited for mid-sized or larger lathes that handle bigger projects.

A wood lathe is easiest to operate and control if it’s located at elbow level.

It’s always a good idea to bolt it down, whether you’re bolting it to the floor or to a workbench.

You should wear eye and face protection. What’s also important is what you don’t wear—never wear anything loose that could get caught in the lathe. Also, be sure to tie back long hair.

One year per inch of thickness is a standard minimum for air-dried wood.

Meet the Tester

Glenda Taylor is a contractor, product tester, and writer focusing primarily on construction, DIY tools, and home appliances.

Additional research provided by Timothy Dale.