We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Highlights

- Furnace control board replacement cost typically ranges from $50 to $900, though most homeowners spend an average of $500.

- The cost to replace a control board depends on local labor rates, inspection fees, and the potential need for other services, such as maintenance or additional repairs.

- When the home’s temperature or furnace operation becomes inconsistent, or when flashing lights appear on the control board, it’s time to get the control board repaired to regain energy efficiency and a comfortable home.

- Some furnaces have legends to troubleshoot the cause of flashing lights, but since there are electrical or gas components to a furnace, repairs are best left to licensed and trained service technicians.

In the winter months, a fully functioning furnace is a necessity. If a homeowner notices inconsistent temperatures in the home or notices interrupted furnace cycles or burn marks, they may have a faulty furnace control board. A furnace control board tells the unit when to turn on, how long to run, and when to shut off. A control board should reliably help to keep a home safe and warm during chilly months and sudden cold snaps.

“The furnace control board is like the brain of the unit,” explains Mack Shwert, HVAC technician at HomeServe. “It controls all the actions of all the working components of the furnace and allows it to operate in a safe manner. All the safeties and loads report back to the control board, which says it’s working properly so the next sequence of operations can happen.”

However, nothing lasts forever, including furnace control boards. With exposure to heat or moisture as well as standard wear and tear, a control board may need to be replaced after years of excellent operation.

The national average furnace control board replacement cost is $500, though homeowners can expect to pay anywhere from $50 to $900, according to Angi. Several factors influence the final cost, including furnace inspection fees, labor costs, and the potential need for additional furnace repairs.

Factors in Calculating Furnace Control Board Replacement Cost

The cost to replace a furnace control board goes beyond the price of the part itself. Factors such as labor expenses, unforeseen emergency services, and additional repairs all play a role in the final price. Understanding the main cost factors can help homeowners properly budget for a control board replacement.

Furnace Type

Another factor that can affect furnace control board replacement cost is the type of furnace in the home. According to Shwert, “Naturally the cost of a control board for communicating in a variable-speed motor furnace will be significantly higher than a control board for a single-stage, chimney-vented PSC [permanent split capacitor] motor furnace.”

More complex furnaces, such as variable-speed ones, require more advanced control boards to handle tasks such as heating sequences. Simpler furnaces will require simpler control boards. Unsurprisingly, the cost for a furnace control board replacement will be higher if the furnace requires an advanced control board than if it requires a simple one.

Labor

Labor is one of the most essential factors when homeowners are budgeting for a furnace control board replacement. Labor costs vary greatly from $50 to $150 per hour. Professionals with more experience might charge more for their furnace services, especially if demand is high. Additionally, labor costs in urban areas are typically higher than in more rural locations. A more complex or time-consuming control board replacement may also incur higher labor costs.

When budgeting, homeowners are advised to put aside between $150 and $450 for labor costs. As homeowners obtain quotes for furnace control board replacement costs, it’s best to ask for an itemized estimate up front, as some technicians offer a flat rate, while others charge by the hour.

Furnace Inspection

An inspection thoroughly examines a unit to ensure that all the different furnace parts are functioning correctly. A furnace inspection can help identify issues before they lead to significant malfunctions within the unit or, in a worst-case scenario, a total furnace breakdown. This is where HVAC service costs can help to prevent major malfunctions by catching small problems early before they escalate into catastrophic failure.

An inspection before a replacement can verify the control board is indeed the root issue and prevent unnecessary costs and frustration. A furnace inspection has its own associated fee apart from the control board replacement cost, typically ranging from $80 to $100.

Maintenance

All furnaces require maintenance, including routine checks, cleanings, and minor repairs. Keeping up with maintenance ensures a furnace operates smoothly and efficiently.

Common maintenance services:

- Annual inspections

- Furnace filter cleaning or replacement every few months

- Checkups and maintenance of ignition systems, burners, and other components

- Lubrication of moving parts

- Checkups and cleaning of blower components to ensure proper airflow

Regular maintenance can help catch issues early, including control board failures. Overheating or dust accumulation caused by a lack of maintenance can cause premature failure in a control board.

Homeowners might spend between $120 and $500 on annual furnace maintenance, including the cost of furnace cleaning, but this investment often leads to savings by extending the life of the furnace control panel and other vital components.

Emergency Furnace Services

After-hours work and work performed over the holidays often constitute emergency furnace services. They’re typically needed due to sudden breakdowns during dangerous cold snaps or due to poor maintenance. Emergency furnace repairs come with a premium fee compared to the fees for regular maintenance and prescheduled repair services.

Emergency furnace services typically cost between $90 and $230 per hour, not including any necessary parts. When a furnace control board fails suddenly, such as in a power surge, it may take an emergency furnace service to get the unit up and running again.

Annual furnace tune-up costs are worth the benefit of early detection of a failing control board before it becomes an emergency, helping homeowners avoid this additional cost.

Additional Furnace Repairs

When homeowners are replacing a furnace control board, other problems may be uncovered within the unit that also need addressing, which can increase the total repair cost. This scenario is especially true with older furnaces or units that have not received routine maintenance.

From furnace blower motor replacement costs to duct replacement prices and coil replacement fees, a control board replacement job can quickly change in scope and cost.

It’s important to note that when the cost of furnace repairs starts to approach 50 percent of the cost of a new system, or if the furnace is nearing the end of its expected lifespan, it’s wise for homeowners to weigh the pros and cons of a complete replacement versus continued repairs. According to Shwert, “If the unit is 15-plus years old, not in great condition, and the unit is inefficient, then it is worth considering replacing it.” Homeowners will want to weigh the cost of a new furnace against the cost of furnace repair.

| Furnace Repair or Replacement Type | Average Cost Range (Materials and Labor) |

| Blower fan replacement | $400 to $700 |

| Circuit board repair or replacement | $100 to $600 |

| Compressor replacement | $750 to $2,000 |

| Condenser coil replacement | $500 to $1,500 |

| Condenser fan motor replacement | $200 to $500 |

| Ductwork replacement | $500 to $2,000 |

| Evaporator coil replacement | $400 to $1,000 |

| Furnace replacement | $2,600 to $6,200 |

| HVAC fan motor replacement | $200 to $700 |

| HVAC TXV replacement | $100 to $500 |

Do I need a furnace control board replacement?

Diagnosing furnace problems correctly and promptly is crucial when a unit malfunctions. Homeowners can look for common signs that a furnace’s control board needs to be replaced.

Flashing Warning Lights

Also known as diagnostic lights, furnace warning lights communicate the unit’s status or potential issues. Modern furnaces often have a small window into the control area, so the lights are viewable without homeowners having to take the unit apart. The access panel may need to be removed on older units in order for the diagnostic lights on or near the furnace’s control board to be visible.

A solid green or continuous green light often indicates normal operation, though this can vary by manufacturer. Flashing or blinking red lights can indicate a problem or error, such as a faulty control board. Some warning lights have patterns for different error codes, making it easier for technicians to diagnose the issue behind the warning.

If a homeowner observes an unusual pattern or combination of flashing lights from their furnace, they’re advised to check the unit’s operational manual and match the blinking pattern with the error. Sometimes a legend for the light patterns is attached to the furnace for easy viewing. Consulting a professional HVAC technician is the next best step if the diagnosis is unclear or if, while homeowners are inspecting the furnace control board, no lights are illuminated at all.

Temperature Instability

Temperatures can fluctuate inside a house for several reasons. Poor or deteriorating insulation is a common issue that can make it easier for outside air to infiltrate a home, making it challenging to maintain a comfortable temperature. Blocked or leaky ductwork can also cause some temperatures to fluctuate between different areas of a house.

However, issues with different components of the HVAC system can also lead to varying temperatures. When it comes to furnaces, a faulty control board is often the cause of temperature instability, especially if the thermostat is in good working order.

If it’s become nearly impossible to keep a home consistently comfortable, homeowners may find it’s worth considering that the furnace control board could be the issue. If other potential causes have been ruled out, homeowners are advised to consult with a professional HVAC technician to determine if the control board needs to be repaired or replaced.

Interrupted Furnace Cycles

Also known as short-cycling, interrupted furnace cycles occur when a furnace turns on and off several times during a short period instead of running a complete heating cycle. Inconsistent temperatures, increased operational noise, and higher utility bills are all signs of a furnace unable to run a full cycle.

A dirty or clogged air filter can cause a furnace to shut down prematurely, as can a faulty thermostat or flame sensor issues. However, a failing control board can also prevent a furnace from running a complete heating cycle. The board may be unable to communicate correctly with different components, causing the unit to shut down improperly. A malfunctioning board might also incorrectly diagnose a nonexistent issue and interrupt the cycle as a safety precaution.

Homeowners are encouraged to contact an HVAC professional for an analysis if their home’s furnace cannot complete an entire cycle.

Burn Marks

Burn marks on electrical components are always cause for concern. There are several potential reasons for burn marks on or around a furnace’s control board, from electrical overloads and faulty wiring to loose connections and overheating components.

If a burned or electrical odor is coming from a furnace, it warrants a prompt inspection. If there are dark, charred, or discolored spots on the control board, the homeowner is advised to immediately turn off the unit and schedule a consultation with an HVAC technician as soon as possible. It’s also important to note that the job is best left to the professionals due to the complexity and risk of a repair involving electrical failure that caused the burn marks.

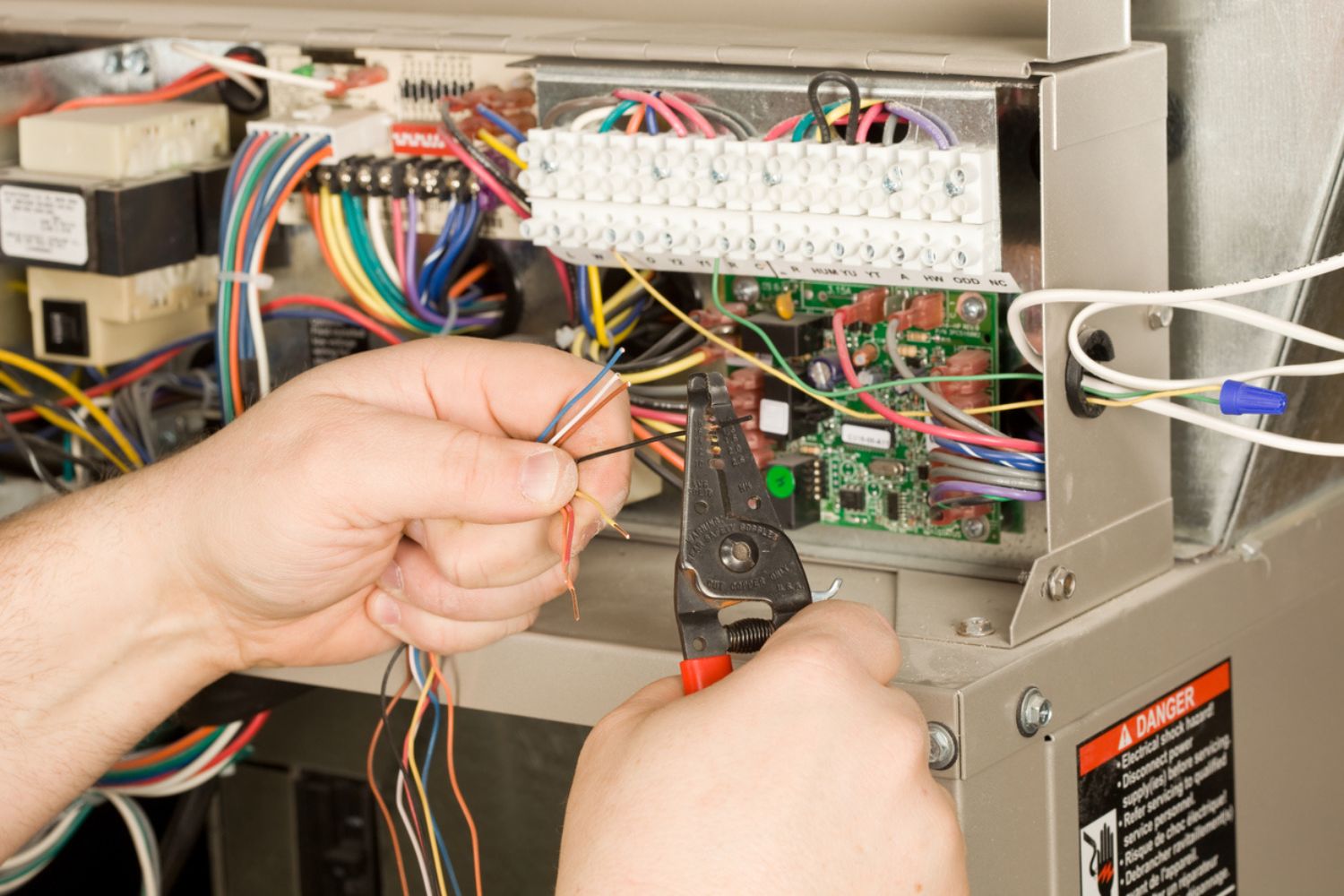

Furnace Control Board Replacement: DIY vs. Hiring a Professional

When it’s evident that a furnace’s control board needs to be replaced, the next question homeowners generally ask is if they can tackle the job or if it’s better to hire a professional. The DIY route has the potential for cost savings, since a homeowner needs to pay only for parts and not for labor.

But even if the control board is the suspected culprit of a malfunctioning furnace, the reality is that there could be several other issues at hand, from worn-out ball bearings and loose wires to clogged filters. There are also different types of circuit boards to consider, which can be difficult for novice DIYers to master. Furnaces also involve electricity and sometimes gas, making them potentially dangerous to work on for inexperienced DIYers, since many states require a licensed professional to complete repairs.

“If you miswire the board, then you could blow the fuse or, even worse, short out the board,” warns Shwert. “Then you are out the cost of the board. Also, on most high-efficiency units, you have to set up the airflow on the control board for heating and cooling. Hiring a professional ensures the proper board will go back in and all of the settings (heating/cooling airflow, staging, delays) will be properly set up with the board and that your unit will be running at peak performance.”

While hiring a professional may have a higher upfront cost than DIY, it’s the safest route for homeowners who are not experienced technicians themselves. An HVAC tech can likely do furnace troubleshooting and complete an electric or gas furnace control board replacement in under an hour. Professionals also have the knowledge and equipment to handle repairs safely, and many guarantee their work, so homeowners know they’re paying for quality repair.

How to Save Money on Furnace Control Board Replacement Cost

Replacing a furnace control board is more affordable than replacing the entire furnace. But that doesn’t mean homeowners aren’t looking for ways to save money. There are a few tips homeowners can use to minimize furnace control board repair costs without sacrificing quality.

- Stay proactive. Addressing minor concerns as soon as they pop up can prevent them from escalating into costlier problems.

- Perform regular maintenance. Keeping up with annual inspections and furnace tune-ups with a licensed technician can help homeowners catch issues early and ensure a unit lasts as long as possible.

- DIY the maintenance. Simple tasks, such as changing air filters and cleaning around the unit (indoor and outdoor), can be handled by a homeowner to boost furnace efficiency.

- Shop around. When a replacement is inevitable, it’s recommended that homeowners reach out for estimates from several professionals to ensure they’re receiving a competitive rate.

- Perform system upgrades. If an older furnace model needs more than control board replacement or repair, consider upgrading the entire system. The best furnace brands offer better energy savings that can offset costs over time.

- Get a home warranty. The best home warranties, such as those offered by American Home Shield and AFC Home Club, can help cover furnace repair costs, including furnace control board replacement costs.

Questions to Ask About Furnace Control Board Replacement

The process to find the best HVAC company (such as One Hour Heating & Air Conditioning or AireServ) for a replacement control board can involve asking about experience, pricing, and processes. Here are some potential questions a homeowner might ask when vetting a pro.

- Are you licensed and insured to handle furnace control board replacements?

- Can you provide a list of references or reviews to showcase your experience?

- Do you have experience with my specific brand and model of HVAC system?

- How flexible is your schedule, and when can you add my replacement to your calendar?

- Will you handle all the necessary permits for the job?

- What are your payment requirements?

- How much life does my unit have left in it? Should I consider a full replacement yet?

- What warranties or guarantees come with my new control board and its installation?

- How often should I schedule regular maintenance for my system based on its current condition?

- How do newer HVAC models compare to my current unit in terms of energy efficiency?

- Do you offer routine furnace inspections near me?

FAQs

A control board acts as a furnace motherboard, controlling every internal component to help a home stay comfortable and warm. As an HVAC unit ages, the control board will likely show signs that it’s beginning to break down and may need to be replaced.

Homeowners who know what to expect regarding furnace control board replacement costs can make informed decisions that help keep their homes comfortable without going over budget. The following FAQ section may provide insight for those with additional concerns about control board replacements.

Q. How long does a control board last on a furnace?

A control board can last for 15 to 20 years, which is about how long a furnace lasts. But it’s worth noting that smaller control board components can sometimes give out earlier. Power surges are a common cause of premature control board failure.

Q. What causes a furnace control board to fail?

A furnace control board can fail for a variety of reasons. The natural aging process of the unit can impact the performance of older boards. Loose wires or unintentional contact with water can also cause a control board to fail. Control boards have a transistor, and its constant exposure to heat can lead to excessive wear and tear, making a control board unable to function correctly.

Q. Is it worth replacing a circuit board on a furnace?

Replacing a failing furnace circuit board can be cost-effective in a newer model. However, a full furnace replacement might be the more practical choice for an older furnace nearing its expected lifespan when other repairs are also adding up. Replacing a bad circuit board in a furnace may add only another 5 years of use, while investing in the cost of a new furnace can offer safe and more energy-efficient heating for up to 20 years.

Sources: Angi, HomeAdvisor, Christianson