We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

When the weather cools, it’s a perfect time to gird your garage against the colder temperatures on the way, especially if you’ve got your home workshop in there. Metal garage doors block strong winds but do little to maintain a comfortable temperature.

But if you’re not ready to plunk down more than a thousand dollars for a new, pre-insulated door, consider gearing up the garage door you’ve got. We’ve assembled all the info you need to understand how to insulate a garage door successfully, plus tips to help you get maximum benefit out of the project.

The Benefits of Insulating a Garage Door

Adding insulation to the door’s interior channels can help keep your garage an average of 10 to 12 degrees Fahrenheit warmer in winter, and as much as 20 degrees cooler in summer. An insulated garage door reduces noise transfer, so not only will you avoid hearing street traffic when you’re inside your workshop, but you’ll also spare your neighbors the sounds of your son’s garage band practice.

The Upside of Using a Garage Door Insulation Kit

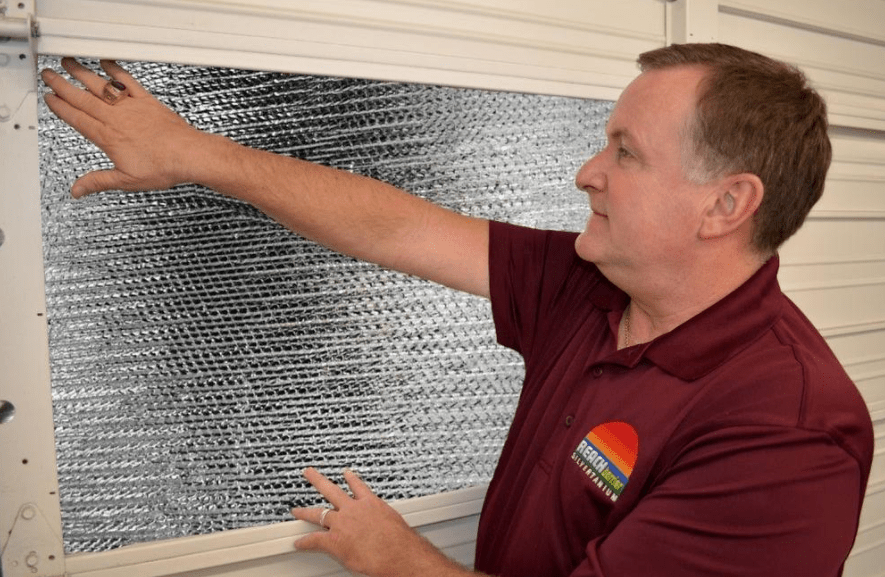

The simplest way to insulate a garage door is with a kit containing either vinyl- or foil-faced batts or foil-faced rigid foam boards. Garage door insulation kits, such as the Reach Barrier garage door insulation kit, start around $50. Some kits cost more but include all the supplies you need—adhesive, tape, a utility knife, gloves, and perhaps even a dust mask. That’s all in addition, of course, to garage door insulation panels that are precut to standard size.

However, the prime benefit of using an insulation kit is that it comes with specially designed retainer pins. Made of lightweight plastic or metal, the pins have plates attached that adhere to the back of the garage door channels to help anchor rigid foam or batts in place. This stabilizes the insulation, so it won’t fall on your car when the door is open. If you choose not to use a garage insulation kit, you can use other methods to hold the insulation in place. (See our tested guide to the best garage door insulation kits for our recommendations for top products.)

What to Know About R-Values and Garage Insulation

A typical garage door is made from metal and offers very little protection from outdoor temperatures. Insulating can help, but not all types of insulation can be considered the best insulation for garage doors.

Insulation is categorized by its ability to reduce heat and cold transfer. The higher the insulation’s thermal-resistance value, or R-value, the better it will stop heat and cold transmission. A few points to consider:

- The thicker the insulation, the higher the R-value.

- When batt-type insulation is compressed or gets wet, its R-value is reduced.

- For the best overall thermal resistance, consider insulating bare stud walls as well as the door.

- Insulation with a high R-value will not significantly reduce thermal transfer if the garage is drafty and cold air flows in.

Choosing the Right Type of Garage Door Insulation for Your Home

Boards or batts? This is one of the first questions you’ll have to answer before starting a garage door insulation project. From there, you’ll just need to think about the sizing and R-value that’s right for your space. Ahead, learn the pros and cons of rigid foam board panels and rolled batt insulation.

Rigid Foam Insulation

Passing on the insulation kit? Most DIYers opt for foil-faced rigid foam board panels that you measure and cut with a sharp utility knife or table saw to fit the channels inside your garage door.

There are three main types of foam board, and they are all acceptable for garage door insulation as long as they are foil-faced and fire-rated. Do not use non-faced foam board, which is flammable and will produce dangerous fumes if it burns; in fact, using it might violate your local building codes.

- Expanded polystyrene (EPS): Available in various-size panels, expanded polystyrene foam can be either rigid or slightly flexible and used to line the inside of a garage door. It resists damage from both moisture and heat, and it has an R-value of about 4.6 per inch of thickness. It’s available in variously sized sheets and comes faced or unfaced.

- Extruded polystyrene (XPS): It’s not difficult to identify extruded polystyrene—it comes in blue-, pink-, or green-colored foam boards. It offers an insulating value of R-5 per inch of thickness. It’s available in both faced garage door insulation panels and unfaced.

- Polyisocyanurate (ISO): All polyisocyanurate foam panels are faced (often with foil) because the boards are manufactured by spraying a liquid against a substrate. Polyiso is often used in roofing but is a suitable option for insulating a garage door. It offers a high R-5.8 insulating value per inch of thickness.

Choose foam board that’s slightly thinner than the thickness of the door’s interior channel enclosures. For example, a standard garage door channel is about 1¾ inches deep, so you would want to cut pieces from a 1½-inch-thick foam board.

Although they can vary, most garage door channels have “lips” that hold the boards in the channels, but rigid foam boards can still rattle around a bit if they don’t fit snugly. A bit of foam-safe adhesive, applied to the back of the garage door channel before inserting a board, will help hold it in place.

If necessary, you can use expanding foam to seal gaps around the sides of the boards, but keep in mind that a little expanding foam goes a long way. Check the label of any adhesive and expanding foam spray to ensure compatibility with the foam board you’re using—some adhesive will melt foam board.

Batt Insulation

Batt insulation doesn’t refer to a specific type of insulation but rather indicates the material’s form—either strips or rolls. Batt insulation is made from various components and is available faced or unfaced. It comes in garage door insulating kits as well as standard batts. Unlike rigid foam, batts are flexible and soft.

Standard batt insulation is readily available, and you might even have an extra roll lying around. While it’s often slightly cheaper than foam board, it’s probably not the best choice for garage door insulation if you’re not using a garage door insulation kit. The thinnest standard batt, at 3½ inches thick, is too thick for most garage door channels, and compressing the batts greatly reduces their ability to insulate a garage door.

If you’re set on batt insulation, find thinner, 1½-inch-thick foil-faced batting—the kind used for wrapping HVAC ducts. It’s available at plumbing supply stores or you can order it online (home improvement centers don’t often carry it). The 1½-inch-thick Johns Manville batt insulation is well suited to the task. To hold the batts in place, you’ll also need to use the correct adhesive and tape recommended by the batting manufacturer.

- Fiberglass batt insulation: The most common type of batt insulation and the most affordable, fiberglass batts are made from thinly spun threads of glass. They come in strips and rolls. A 1½-inch-thick fiberglass batt offers a thermal resistance value of R-4.7 to R-6.45, depending on density.

- Rockwool batt insulation: Also known as mineral or slag insulation, Rockwool insulation is the byproduct of recycled steel that’s blown into fibers at intensely high temperatures. Depending on density, a 1½-inch-thick Rockwool batt has an R-value between R-4.3 and R-5.16.

- Ceramic batt insulation: A relatively new kid on the block, ceramic batt insulation is made from spun ceramic fibers and is mainly used for insulating around high-heat appliances, such as furnaces, but it can also be suitable for insulating garage doors. It’s a bit more expensive than fiberglass or Rockwool, but it provides an R-6.45 thermal value per 1½-inch batt.

Making the Most of Your Insulation Project

To make the most of your garage door insulation project, replace the rubber sweep on the bottom of the door. Also, be sure to install weatherstripping around the sides of the garage door to prevent icy drafts from blowing in. And while insulating the doors is a significant first step, you’ll enjoy more heat retention if the rest of your garage is protected as well—heat can still escape through a non-insulated roof or sidewalls.

Any steps you can take before Old Man Winter comes calling will keep you toastier inside your workshop. But we warn you: Now you’ll have no excuses not to get things done in the garage this winter.

Final Thoughts

For those who use their garages year-round as workshops, insulated garage doors can make the difference between working on projects in relative comfort or not using the workshop at all during the coldest or hottest seasons.

Insulating a garage door should be undertaken in conjunction with installing weatherstripping around a walk-through door, a threshold seal at the bottom of the door, and (optimally) adding batt insulation in open stud walls. Some garage doors also have gaps around their perimeter, and sealing these is a vital step in getting the garage ready for winter.

FAQs

The least expensive method is to insulate the door with fiberglass batts approximately 1½ inches thick.

Most types of insulation are lightweight, and an insulated garage door should not be appreciably heavier than an uninsulated one. In addition, insulation should not affect the ability of a garage door opener to open and close the door.

That will depend on the thickness of the insulation. A 1-inch-thick foam EPS foam board offers a thermal resistance value of about R-4.5, while a 1½-inch-thick Rockwool batt can provide up to R-5.16.

It does make sense if other air gaps are sealed in the garage and the stud spaces are also insulated. If the garage is drafty, however, an insulated door won’t make much difference.

If the garage door receives direct sunrays from the south or west, insulating it can help keep the temps inside the garage from soaring during the hot summer months.