We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

A backyard deck can be the perfect platform for good times, but a wooden surface needs a proper sealant to protect it against the ravages of sun, rain, and temperature fluctuations. While you can hire a decking contractor to seal the surface, many homeowners opt to tackle the task themselves—and save $551 to $1,292, according to HomeAdvisor.

Sealing a wooden deck isn’t a difficult DIY project for a homeowner. Choosing the appropriate sealant for your deck (our researched guide to the best deck sealers is a good place to start) is the first step to ensuring quality results. Once the product is in hand, follow our expert tips and tricks for sealing a deck to get the job done right.

DO wait 30 days before sealing a new deck.

If you’ve just built a new deck, you’re probably itching to finish the job by sealing it. But preservatives in the wood often require about 30 days’ dwell time before the deck can soak up the sealant.

After a 30-day period, pour some water on your deck. If it beads up, the wood is still too wet to seal. If the water is absorbed, it’s ready to seal. Be sure to apply sealant as soon as the wood is ready. Leaving the deck exposed any longer increases the likelihood of damage from both ultraviolet (UV) rays and moisture.

DON’T confuse paint, stain, and sealant.

Sealant, stain, and paint can all be applied to a deck for different degrees of protection.

- Sealants are primarily used to protect against moisture damage. They contain waterproof or water-repellant properties and have a thicker viscosity than stains. While they exist, it’s unusual to find a clear deck sealer with UV protection. The reason for this is that unlike stains, sealants often lack the pigmentation that naturally blocks UV rays.

- Stains are always pigmented—they both add color to the deck and protect against UV damage. Even the best deck stain generally offers only moderate moisture protection, but it is still better protection than nothing.

- Paint, be it latex or oil-based, can protect against both UV and moisture damage, but the best deck paint generally doesn’t hold up as long as sealant or stain. The other thing to know about deck paint is if there’s any lingering moisture in the wood during application, it is susceptible to bubbling and chipping.

Bottom line: A combined stain-and-sealant product offers durable moisture and UV protection with little downside. Short of this 2-in-1-type product, you can always apply a stain to the deck and, after 48 hours, apply sealant to achieve a similar level of protection.

RELATED: What’s the Difference? Painting vs. Staining the Deck

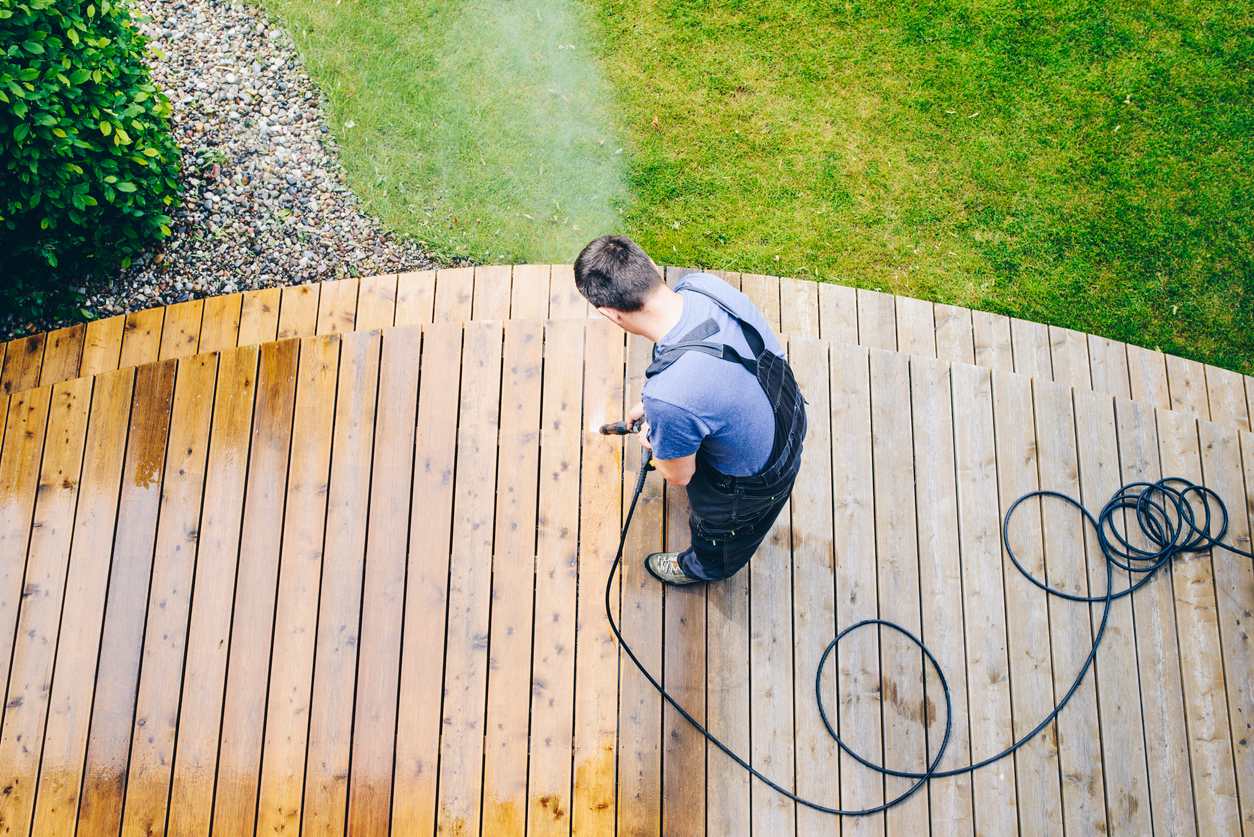

DO repair, wash, and sand your deck before sealing it.

Proper prep is key to a successful deck sealing. Begin by repairing or replacing any loose or broken boards. Then, use a power washer to scrub the surface clean. Allow the deck to dry for 24 hours, then sand the surface with 60- to 150-grit sandpaper or a sanding disk. Use a powered sanding tool to remove the top layer of wood, which could act as a barrier to the sealant.

If your deck has old sealant on it, it’s especially important to sand the entire surface—attend to areas where the sealant has worn away as well as those that still have moisture protection intact. Remaining patches of the old sealant will prevent new sealant from being absorbed, so sand evenly to ensure a clean, bare surface.

Finally, sweep or vacuum the wood thoroughly. Even a new deck will need at least a brief washing and drying to banish any dirt and grime that has accumulated during the initial 30-day drying period.

DON’T apply deck sealant to damp or frosty surfaces.

Applying sealant to a damp or frosty deck will lead, at best, to an uneven, splotchy seal that can’t effectively protect your deck. At worst, the sealant will bead up on the water and fail to be absorbed, creating a messy, dangerous slipping hazard. Always allow the deck’s surface to dry for at least 24 hours after a rainfall, and check the surface to make sure that it is ready to absorb the sealant before sealing the deck.

DO use proper tools and technique for sealing a deck.

Deck sealant can be applied using a roller, a paint brush, or even a paint sprayer. You can either work from a standing position using an extending pole, or on your hands and knees (if you take the hands-and-knees approach, we recommend wearing knee pads). Work slowly and methodically to ensure every inch of the deck gets adequate coverage.

Overly thick sealant is prone to peeling and chipping, so avoid oversaturating the surface by applying only one coat of sealant at a time. In most cases all you’ll need is one coat, but if you decide to apply a second coat, wait at least 24 hours.

DON’T disregard temperature and time of day.

Plan to seal your deck when both the temperature and time of day are ideal. Aim for a pleasant, not-too-windy day between 50 and 90 degrees Fahrenheit. Get to work in the morning, as the hot sun of a summer afternoon can cause sealant to evaporate quickly, preventing it from absorbing properly.

DO apply a sealant-and-stain product once a year.

It’s a good idea to apply a good deck stain and sealer at least once a year, depending on your climate zone and the age of your deck. In sunnier regions, adhere strictly to a once-a-year schedule to protect the wood from powerful UV rays.

Northern regions may get away with sealing and staining every two, or even three, years. Bear in mind, though, that decks in these regions are more susceptible to moisture damage. Northern residents should be extra vigilant about sanding the deck before sealing it. You want to make sure that the sealant soaks into the wood and provides long-term protection against snow and other moisture damage.

RELATED: How To Restore a Weathered Deck

DON’T use the deck for 48 hours after applying wood sealer.

While wood sealant is normally dry to the touch within a few hours, for a proper seal that protects the wood, stay off your deck for 2 full days. Disrupting the drying process can affect how well the wood is sealed, and you could find yourself having to repeat the entire sealing process.

To remind family members to stay off the deck, put yellow caution tape across the patio doors, stairs, and other access routes to the deck. After 48 hours, let the partying begin!

DO cover plants and tape off your siding before sealing.

Whenever you’re using chemicals around plants, it’s a good idea to protect them from possible contamination. A deck sealant’s job is to act as a moisture barrier for wood, and it will have the same effect on plants. Dripping sealant on a plant may prevent it from absorbing the nutrients it needs. It may develop spots and eventually die.

While sealant is being applied, it’s a good idea to use either plastic sheeting or drop cloths to cover plants near the deck. Use painter’s tape, cardboard and drop cloths to cover door trim, siding, and thresholds that lead to the interior of the house. Be careful not to use tape that’s stickier than painter’s tape, as it could peel away the finish from surfaces.

DON’T take shortcuts when resealing a deck.

Shortcuts may help you finish a job early, but they won’t help you finish a job well. If you skip cleaning and repairing a deck prior to sealing, you can end up with a finished deck that lacks color uniformity. The sealer just can’t stick to wood if there are particles on top, so it will stick to the particles instead.

Applying a sealer too thickly is another shortcut to avoid. Doing so can cause uneven drying and discoloration and make it take longer for the sealer to absorb. Don’t try to speed up the job by ignoring dry times and pretending that the deck isn’t still too sticky to walk on. Walking on a deck before it’s dry will mean that you’ll have to repeat the entire process from the very beginning.

DO stir deck sealer thoroughly before applying it.

“Shake or stir?” is a question often asked when using a new paint, stain, or sealant. It’s a safe bet that the answer, at least when it comes to deck sealers, is to stir and not shake. Shaking a sealer can cause the mixture to bubble, and those bubbles will show on the surface of the deck.

In the end, it’s good practice to read the can’s label before applying a sealant—the manufacturer’s recommendations for stirring, shaking, drying times and everything else should be spelled out clearly. If the type on the label is too small to read, snap a photo and enlarge it to get a better look at the instructions.

DON’T treat composite decking the same as wood decking.

While there are general similarities and differences between caring for a wood deck and a composite deck, there is nuance involved when it comes to sealing composite decking. Manufacturers of composite decking stipulate that it does not need to be sealed and only requires a periodic soap-and-water wash (that said, you may find that some deck sealers are promoted as working with certain brands of composite decking). Homeowners should note that solid plastic decking should not be sealed.

Note that the framing under a composite deck is often made from wood, which can be sealed, and sealing this framing can help extend the life of the wooden structure. Plus, any railing elements that are made from wood can benefit from a sealer too.