We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Flattening board faces and squaring their edges is a necessary process at the beginning of woodworking projects, but does everyone really need a jointer? Using a tool for this step corrects cupping and warping in the wood, making it easier to fit the workpieces together for gluing or fastening. For one-off projects, a combination of jointing plane, power planer, router, and/or table saw can do the job; After all, power jointers are big and expensive. On the other hand, frequent (or even occasional) usage may justify the purchase of a power jointer to make the work more efficient. Benchtop jointers have certain limitations that I’ll discuss in this review, but they are an intriguing option for woodworkers who build small projects in small shops. I tested the Rikon 8-inch Helical Style Benchtop Jointer to find out how it would perform in that kind of setting.

Rikon 20-800HSP 8-Inch Benchtop Jointer: At a Glance

Our rating: 4.5/5

Top Pick

Rikon 20-800HSP 8-Inch Benchtop Jointer

| Rikon 20-800HSP Specs | |

| Motor amps | 10 |

| Cutterhead speed | 20,000 RPM |

| Number of HSS inserts | 16 two-sided |

| Maximum cutting width | 8 inches |

| Table dimensions | 30½ inches long, 8 3/16 inches wide |

Testing the Rikon 20-800HSP 8-Inch Benchtop Jointer

Massachusetts-based Rikon Power Tools Inc. designs and engineers woodworking tools and equipment in the US and manufactures in its ISO9001-certified factory in Qingdao, China. Rikon tools enjoy a favorable reputation for initial quality, precision, and durability among serious hobbyists and small-scale professionals.

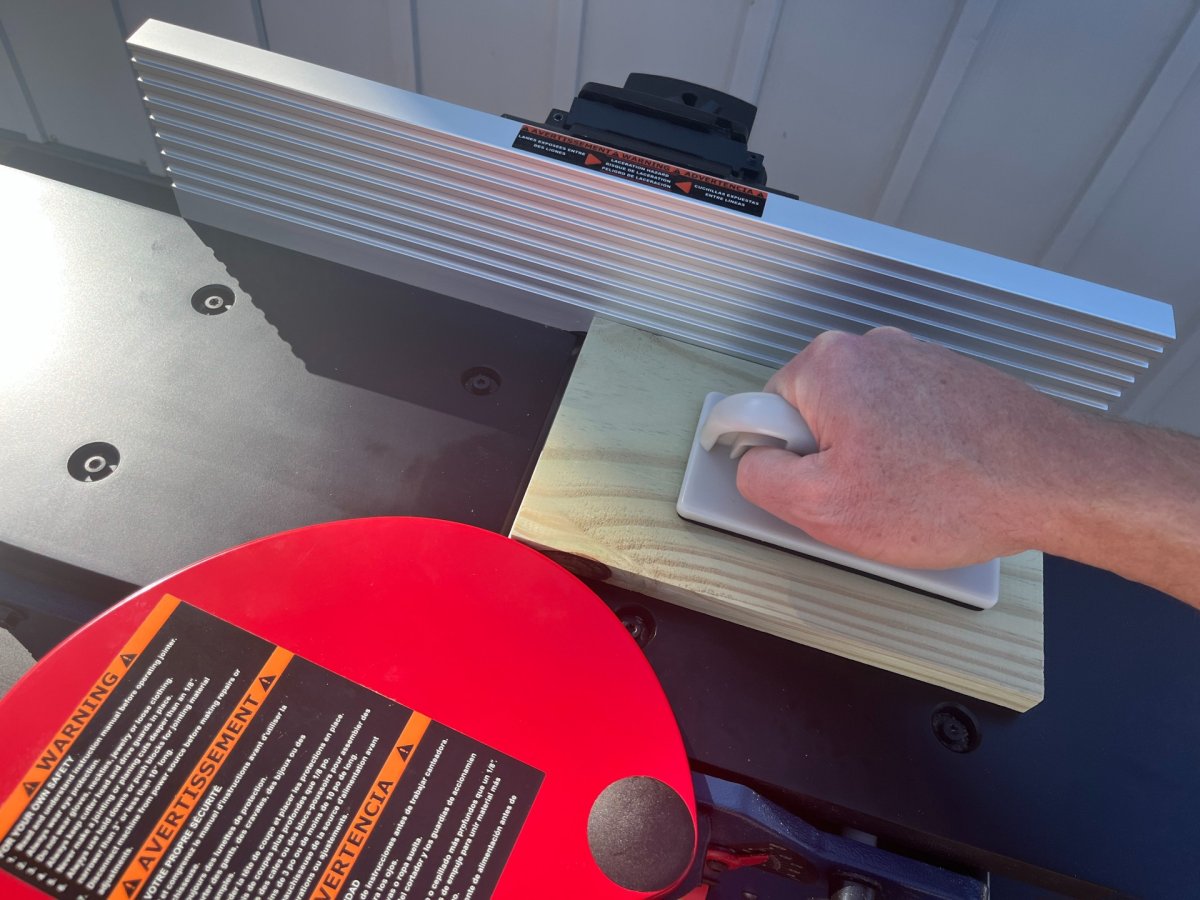

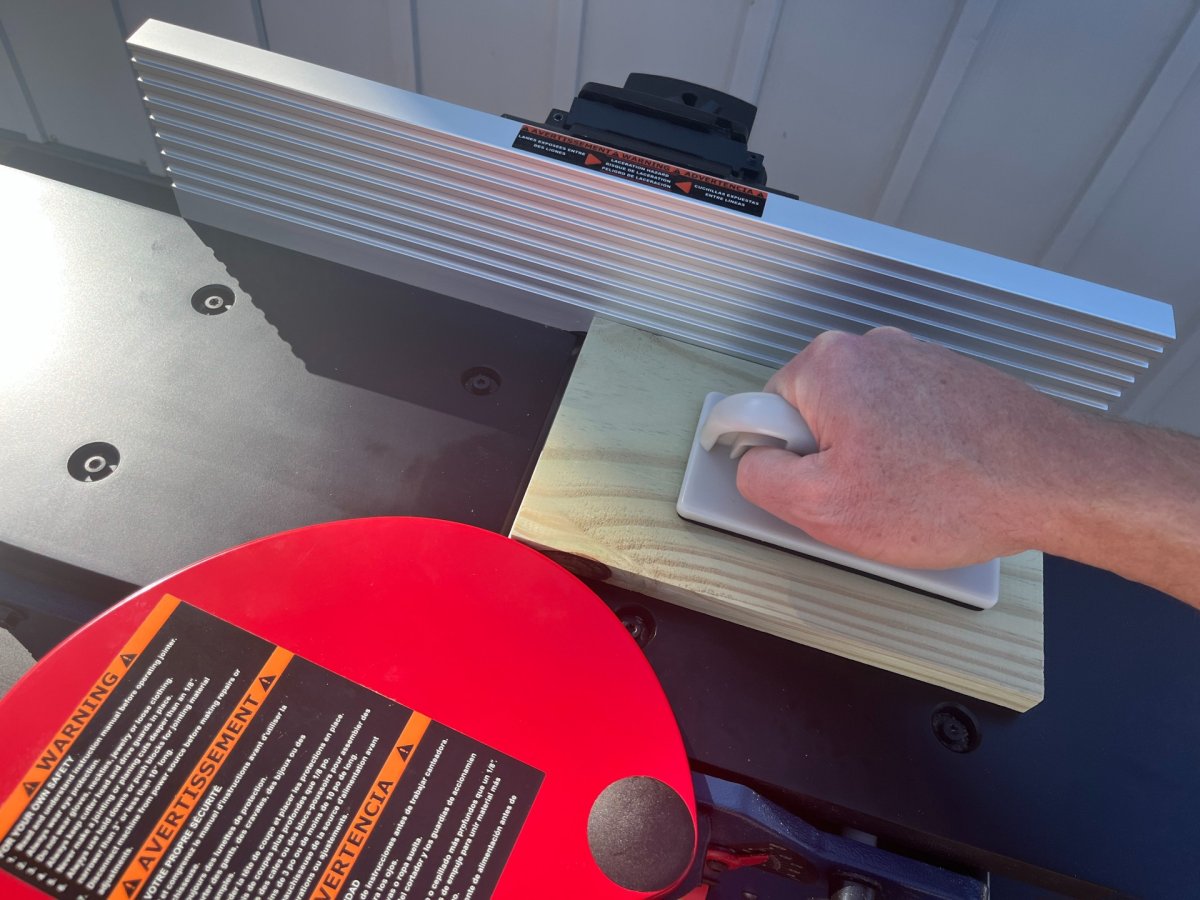

The Rikon 20-800HSP 8-inch Benchtop Jointer features a helical style cutter head, a 90-degree to 135-degree tiltable fence, and an extendable table with a maximum total length of 51½ inches. A 10-amp electric motor turns the cutter at a rate of 20,000 revolutions per minute (RPM). The cutter head is equipped with 16 carbide inserts that have 2 cutting edges—when the initial edge gets nicked or becomes dulled, simply rotate to the fresh side for extended wear.

Over four months, I spent approximately 30 hours testing the Rikon 8-inch Jointer in my small workshop. I have used it for the traditional purpose of flattening and squaring store-bought lumber, and for a similar step in the process of milling boards from logs. Most of the boards I process are less than 6 inches wide and 3 feet long. For those projects, this machine worked perfectly. I have also pushed the limits with longer, wider boards. I based my positive rating on my average use pattern because I believe that is the intended usage pattern of the tool.

| What We Like | What We Don’t Like |

| High RPM cutter processes boards quickly | Loud; requires good ear protection |

| Strong motor resists bogging | No support between table extension bars |

| Nice flat table and square fence | Cutters are not truly helical |

| Durable carbide cutting inserts | |

A Purpose-Built Tool for Small Woodworking Projects

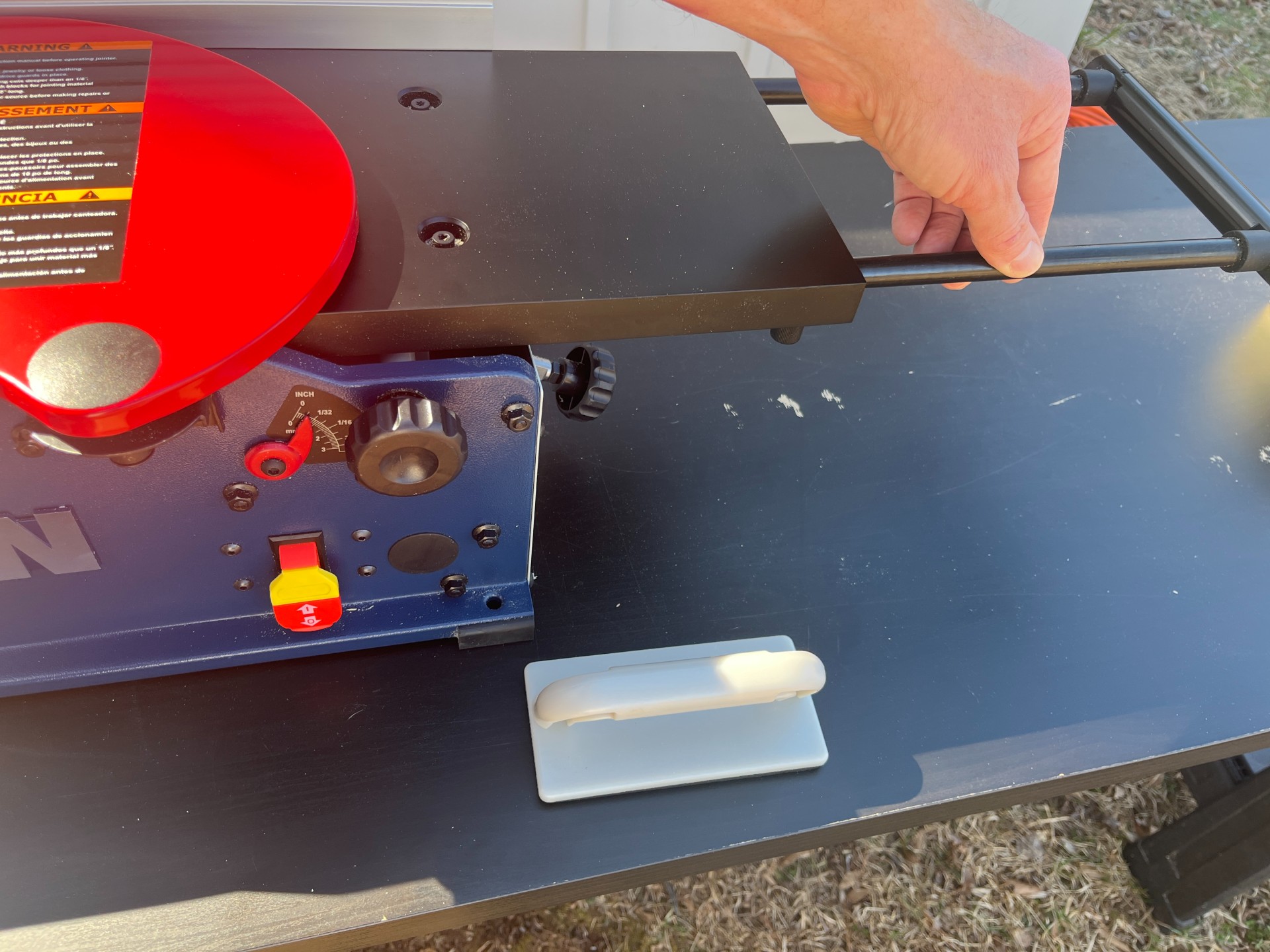

The Rikon 8-inch Jointer extends from 30½ inches to 51½ inches long and measures 18¾ inches wide and 13 inches high. It is a convenient size to set up on a workbench. At 49 pounds, it’s light enough to move in and out of storage but heavy enough to resist movement during operation—whether mounted or relying on the non-skid feet. The 8-inch cutting width allows generous capacity for face jointing, which makes this machine suitable for a wide variety of woodworking projects.

One noteworthy detail about the cutter head is that the 16 carbide inserts are not truly “helical.” The edges are positioned square to the cut, but the cutters are arranged in a “helical” pattern around the head. That being said, I was consistently pleased with the smoothness of the results. Another potential issue is that the fence has a small amount of flex under pressure. In three months I only had to readjust to square once, but it’s something that users will want to monitor, especially when doing a lot of edge work.

Since I am in the habit of crosscutting workpieces to length prior to flattening them, and I didn’t already have a traditional jointer, the comparatively short support bed on the Rikon Jointer made no difference to me. With the extension bars pulled out, I had no problem processing boards up to 6 feet long, but there was a catch. The ends of longer warped or bowed boards would sometimes slip into the void between the extension bars after passing the cross piece of the extension. As an easy and effective fix, I laid scraps of ⅛-inch plywood to bridge the extension bars and keep the boards flush with the table.

Easy to Set Up and Adjust, No Special Wiring Required

Several key features boost the Rikon benchtop jointer’s convenience factor. First, the power cord is a standard 110-volt. Many freestanding jointers require a 220-volt outlet, which is fine if the shop is wired for it. I appreciated the flexibility of this 110-volt benchtop unit. I could plug it into any outlet in my shop, generator, or remote project site without worrying about plug compatibility.

The Rikon also features convenient, simple adjustment systems. This setup could not have been easier in terms of operating adjustment. The fence mount system is equipped with locking levers for quick, secure positioning changes. The tool includes a horizontal positioning adjustment and a tilt adjustment with positive stops at 90 degrees for square corners, and 135 degrees for making 45-degree edge bevels. After initial setup and calibration, which took less than two minutes, positioning remained true throughout the testing period.

As with any cutting machine, blade maintenance is a critical feature—and any machine with fidgety, unstable blades can be dangerous or will sit unused in the shop. The depth of the cut is one important consideration. On this jointer, the cutter head position remains constant, while the infeed table is raised or lowered to adjust the cut depth. Right out of the box, I used a straight edge and followed the calibration procedures outlined in the manual to ensure that the tables and cutter head were properly aligned—they were. Going forward, the only necessary adjustment was to raise or lower the infeed table, depending on the amount of material I needed to remove per pass. Unless the board was severely cupped or extremely rough, I kept it at less than ⅛ inch. The cutter head on this machine is equipped with a set of 16 carbide square inserts that are sharp on two edges. This design eliminates sharpening as would be required with traditional jointer knives. In this case,e the insert edge that is square to the material feed direction does the cutting, leaving the second edge in reserve. When the first edge becomes dull or damaged, I can remove one screw and rotate the insert 90 degrees to activate the second edge. When that one becomes dull or damaged, I will replace it. Since carbide is much tougher than traditional blade steel, I expect to get about twice the production from these inserts compared to the time between sharpening steel jointer knives. After 30 hours, I have not had to rotate the inserts.

Cuts Surprisingly Fast, Leaves an Excellent Finish

I am a hobbyist who sometimes needs to flatten warped boards or make boards from logs for small projects, and this machine has done exactly what I needed. It is loud, so I make sure to wear good ear protection while I work, but it does not seem to be any louder than my DW735 planer. Most of the workpieces that I feed it are 6 inches wide or less, and I usually remove between 1/32 inch and 1/16 inch at a time. In this scenario, the Rikon 20-800HSP processes all types of wood quickly without bogging down and produces a flat, smooth surface. I rarely change the fence, so its ability to remain reliably square is more valuable to me than adjustability. I made a few adjustments as part of the testing process, and it created near-perfect 45-degree bevels each time I tried it.

I find the table extensions to be most helpful whenever I work with boards that are longer than 24 inches. Since I started using plywood to close the gaps between the extension bars, I stored those pieces together with the jointer and installed them right away as part of my setup routine. They eliminated what, in my opinion, was the only real weak point of this tool at no extra cost since I made them from scraps that were lying around the shop.

The only remaining issue that small shop owners might not be prepared for is dust/chip collection. The Rikon benchtop jointer does have a vacuum port beneath the outfeed table, but it does not actively “blow” the debris out. Without a dust collection system or vacuum, it will become clogged with debris fairly quickly. I normally use my wet/dry vacuum for this purpose and it does a decent job, but it does add a device to the available power supply.

A Fair Price for Better Than Average Performance

Selling for $699.99, the Rikon 20-800HSP benchtop jointer is priced slightly higher than comparable models from other manufacturers. Popular models from Grizzly, Wen, and Wahuda range between $400 and $550. All of these jointers have similar cutter heads and table designs, 10-amp motors, and extendable tables. Two key differences are the types of inserts used and the cutting speed—Rikon’s cutter head runs 40 to 50 percent faster than the competitors. Some of the others use high-speed steel (HSS) instead of the more durable carbide cutters on the Rikon unit. This was also the lightest-weight 8-inch jointer we researched, weighing in at 49 pounds. Altogether I think it’s a fair price for a reliable performer.

Buy the Rikon 8-Inch Benchtop Jointer on:

Product Comparisons

| Rikon 20-800HSP | Wahuda 8-Inch Benchtop Jointer | Grizzly G0947 | Wen JT833H | Grizzly G0958 Jointer Planer Combo | |

| Motor amps | 10 | 10 | 10 | 10 | 15 |

| Cutterhead speed | 20,000 RPM | 12,000 RPM | 11,000 RPM | 12,000 RPM | 8,500 RPM |

| Cutter type | 16 2-sided carbide inserts | 16 4-sided carbide inserts | 16 2-sided high-speed steel inserts | 16 high speed steel inserts | 18 4-sided carbide inserts |

| Maximum cutting width | 8 inches | 8 inches | 8 inches | 8 inches | 8 inches |

| Table dimensions | 30½ inches long (extends to 51½ inches), 8 3/16 inches wide | 33 ½ inches long (extends to 51 inches), 8 inches wide | 34 inches long (extends to 52 inches), 8¼ inches wide | 33 inches long (extends to 51 inches), 8 inches wide | 29¼ inches long (fixed), 8¼ inches wide |

| Weight | 49 pounds | 64 pounds | 59 pounds | 55.1 pounds | 57 pounds |

| Price | $699.99 | $549.99 | $462.47 | $406.37 | $669.99 |

So, is the Rikon 8-Inch Benchtop Jointer Right For You?

The Rikon 20-800HSP 8-Inch Benchtop Jointer is not for everyone. It’s a specialty tool at a significant price point that plenty of woodworkers do without, either by purchasing premium wood or by finding creative workarounds using tools they already have. Those who decide to buy a jointer, where space allows, typically prefer big freestanding models that can handle larger workpieces. All of that being said, there are plenty of small scale hobbyists like me who have serious space limitations or simply stick with smaller projects. We are the target market for benchtop models like this one.

For those who are considering a benchtop jointer instead of a large freestanding tool, this one may be ideal. It is fairly lightweight but not flimsy. It was easy to set up and adjust, and consistently produced accurate flat faces and square edges. It may not be the cheapest of its kind, but it offers good value for the price.

Meet the Tester

Mark Wolfe is a writer, product tester and serial DIYer who lives in an older home. When he isn’t writing, he spends his time upgrading, repairing, and replacing anything and everything in his home, yard, and garden. He tests and writes reviews about hand and power tools, lawn care and home repair products, and outdoor living goods.